Manufacturing Equipment Maintenance Software

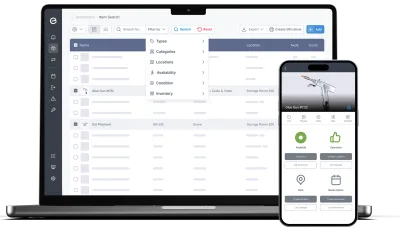

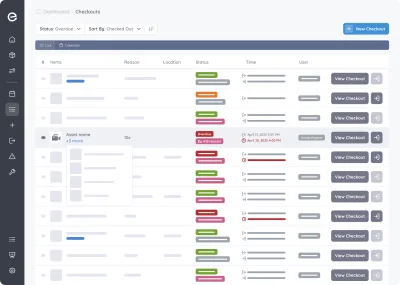

Keep your factory running smoothly with Itefy’s equipment inventory management system. Eliminate downtime, avoid double bookings, and track every machine in real time.

From maintenance to reservations, Itefy gives your team full control and visibility—across shifts, departments, and locations.

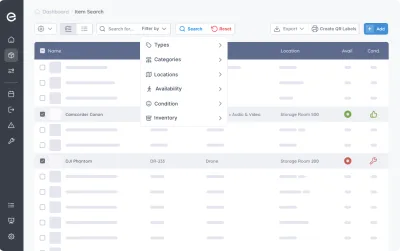

Key features:

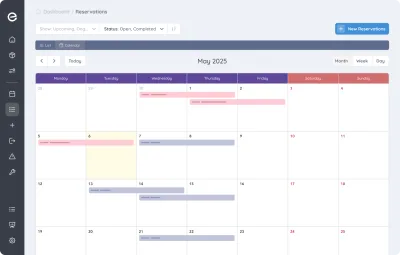

- Prevent equipment downtime

- Track location in real-time

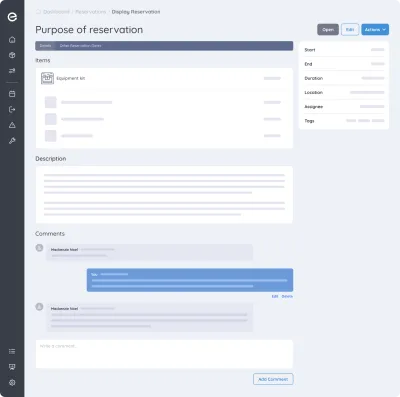

- Avoid double-bookings

- Automate maintenance logs

- Ensure inspection compliance

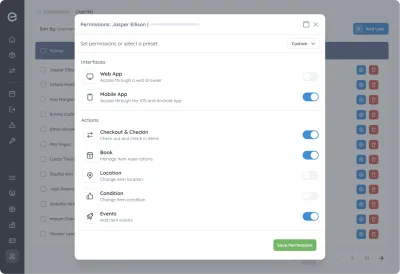

- Assign tool responsibility

- Log issues instantly

- Share visibility across teams