Why Periodic Maintenance Scheduling Is a Must for Businesses

Periodic maintenance scheduling boosts safety, reduces cost, and improves business operations. Learn benefits, implementation, and the best tool to manage it all.

In this article:

- Key Takeaways: Periodic Maintenance Scheduling

- What is Periodic Maintenance Scheduling?

- Why is Periodic Maintenance Scheduling Important?

- 1. Increases Safety and Compliance

- 2. Reduces Long-Term Cost

- 3. Extends Asset Life

- 4. Easy Implementation

- 5. Smoother Operations

- Periodic Maintenance Planning and Scheduling Examples

- Ensure Your Business Runs Smoothly With Scheduled Maintenance

Every piece of equipment has a limited lifespan, and without regular upkeep, wear and tear are inevitable. For businesses that rely on machinery, vehicles, or infrastructure, the cost of reactive maintenance can pile up fast and strain your budget.

That’s where periodic maintenance scheduling comes in. It encourages servicing equipment at regular intervals to prevent sudden breakdowns, reduce operational costs, and maintain a smooth workflow. Think of it as a routine physical checkup. Just as annual checkups prevent illness and prolong your life, periodic maintenance prevents equipment failure and extends the functional life of your assets.

So, what’s included in periodic maintenance scheduling? And how can you implement a maintenance plan that’s both effective and easy to manage? Let’s break it down.

Key Takeaways: Periodic Maintenance Scheduling

- What it is: It is a proactive approach to servicing equipment at regular intervals based on time, usage, condition, and key metrics.

- Benefits: Routine maintenance scheduling enhances safety and extends the lifespan of your assets. It also minimizes unplanned downtime and long-term costs.

- How to Implement: Build an asset inventory and set maintenance intervals and designated responsibilities using the Equipment Management Software. You can also optimize the maintenance schedule by analyzing performance metrics.

What is Periodic Maintenance Scheduling?

Periodic maintenance scheduling involves performing maintenance tasks at regular, pre-defined intervals, regardless of whether the equipment malfunctions or not. These intervals are usually based on time or usage metrics, such as Mean Time Between Failure (MTBF).

The goal is to keep everything running smoothly to prevent costly breakdowns or emergency maintenance issues. It’s cost-effective, easy to implement, and doesn’t require any high-end software. Yet, it delivers prominent results by reducing unexpected failures and extending the equipment's lifespan.

Whether you’re managing HVAC systems, vehicles, or factory machines, a well-planned periodic maintenance schedule provides stability. When your assets are well-maintained, your business runs more smoothly. Because in the end, Healthy machines mean happy teams.

Why is Periodic Maintenance Scheduling Important?

In high-stakes environments, even minor equipment failure can result in missed deadlines, safety violations, and unhappy customers. This makes periodic maintenance scheduling a smart investment. Let's take a look at why it matters:

1. Increases Safety and Compliance

For certain industries, equipment failures can pose a significant hazard. For example, malfunctioning forklifts, jammed conveyor belts, or overheated engines can cause severe injuries. In many cases, the root cause is inadequate inspection and maintenance.

A recent example comes from an OSHA report involving the death of a worker after being struck by the machine’s barrier door. Following the incident, OSHA proposed a total of $1,671,738 in penalties for multiple safety violations. Periodic maintenance helps you avoid these liabilities and protects both your workers and brand reputation.

2. Reduces Long-Term Cost

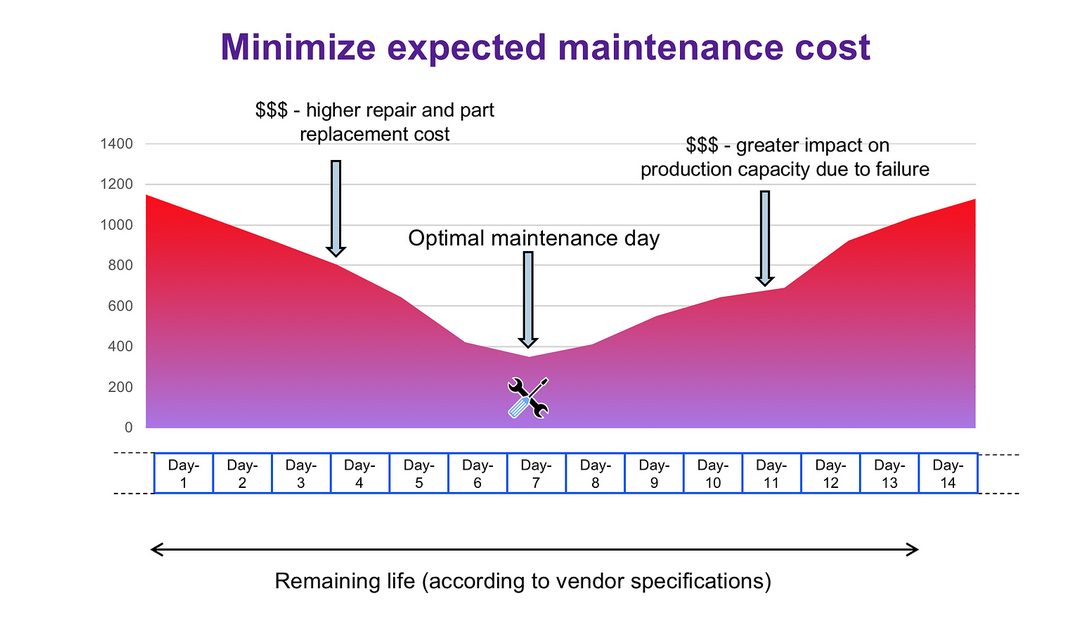

Industry statistics reveal that running equipment to the point of failure can cost up to 10 times more than a regular maintenance program. This shows that proactive repair costs far less than emergency replacements and unplanned repairs.

Routine servicing also ensures that machines operate more efficiently, which cuts down on energy expenses. In fact, businesses that follow a periodic maintenance schedule report saving up to 40% compared to those relying on reactive maintenance.

3. Extends Asset Life

Assets that don’t receive regular care deteriorate more quickly and require earlier replacement. Periodic maintenance saves this expense by extending the usable life of your assets. Routine equipment lubrication, calibration, and cleaning go a long way in preventing the buildup of wear that causes premature failure.

By extending the lifespan of your assets, you can delay costly capital purchases and instead invest in your business growth. Besides improving the durability, regular maintenance also enhances the equipment’s productivity and performance, which positively impacts the company’s credibility.

4. Easy Implementation

The best aspect of periodic maintenance scheduling is its straightforward nature. Most equipment manufacturers usually provide maintenance schedules. You only need to schedule and follow them consistently.

Tools like Computerized Maintenance Management Systems (CMMS) make this process easier by automating task scheduling. It sends reminders and helps store digital maintenance logs, making it easier for you to manage and adopt a regular maintenance routine.

Equipment Management Software: This multi-user equipment management platform helps keep all your equipment information in one place. You can track, manage, and obtain equipment usage reports with just a few clicks. |

5. Smoother Operations

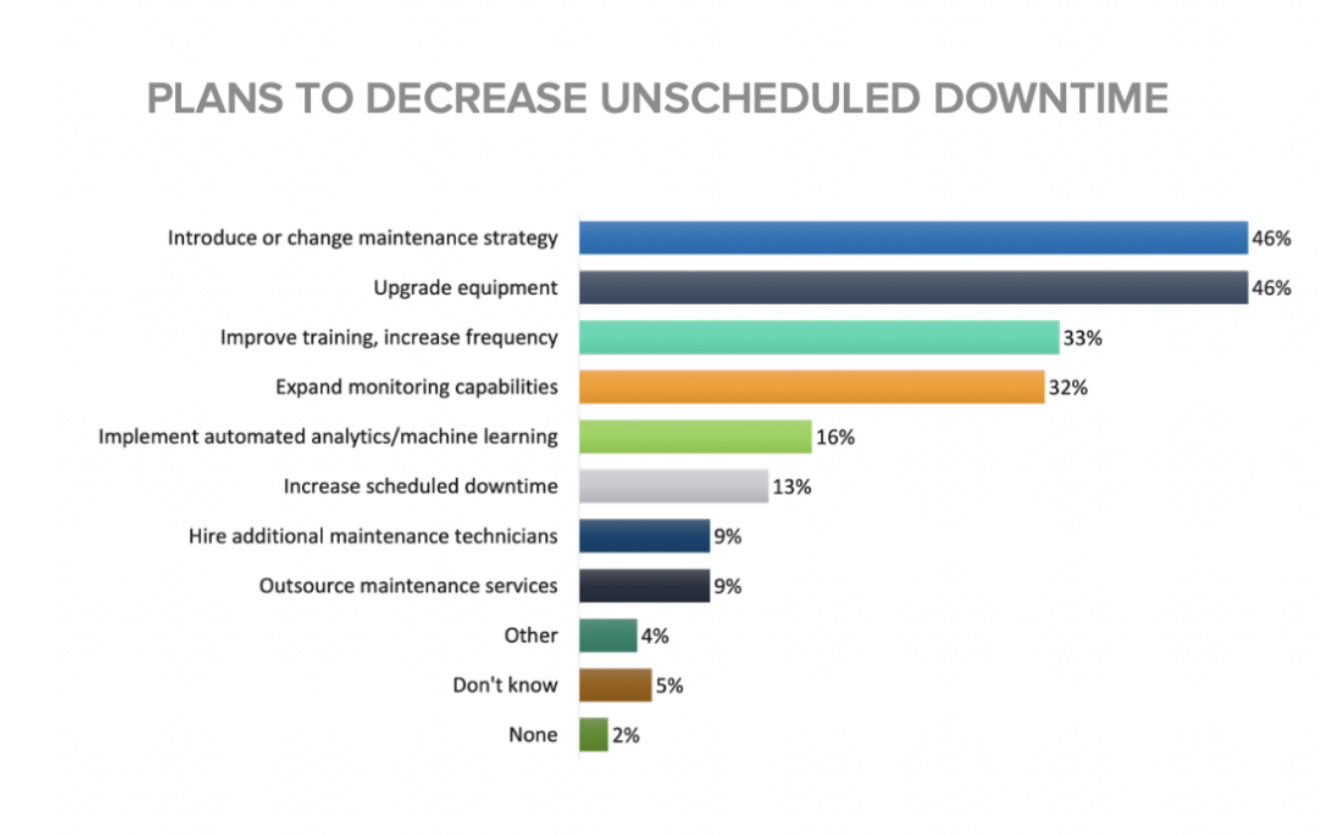

Unplanned downtimes disrupt workflows, throwing off everything from production schedules to customer timelines. According to research, an average manufacturing plant loses 5-20% of its annual productivity due to unexpected downtime.

With periodic maintenance, your assets are serviced before failure, keeping your business operations stable. Additionally, knowing maintenance schedules in advance helps you plan projects better and minimize disruptions.

Periodic Maintenance Planning and Scheduling Examples

Periodic maintenance takes different forms across industries, but its objective remains the same. Whether it’s IT, logistics and transportation, or industrial maintenance, periodic maintenance ensures everything runs smoothly without unexpected hiccups. Here are a few examples of periodic maintenance:

| Industry | Maintenance Tasks |

| Logistics and Transportation |

|

| Office and Commercial Buildings |

|

| Manufacturing and Industrial Settings |

|

| Construction |

|

| Healthcare |

|

Ensure Your Business Runs Smoothly With Scheduled Maintenance

A well-maintained asset operates safely and lasts longer. But you don’t have to wait until it breaks down to call for maintenance. The wise move is to stay ahead with periodic maintenance scheduling using tools like Equipment Management Software.

With automated reminders, centralized logs, and mobile access, you and your team can stay updated with every maintenance task. This helps you derive better value from your assets by providing a clear insight into the inventory.

Frequently Asked Questions

-

The frequency of maintenance depends on the types, condition, usage, and manufacturer’s recommendations. You can track performance data and adjust maintenance intervals based on key metrics to ensure timely and effective maintenance.

-

The main drawbacks of periodic maintenance are:

It requires planning ahead of time, which can be challenging during busy days.

Frequent maintenance tasks may lead to unnecessary costs, especially if the equipment does not require servicing.

By valuing periodic maintenance, companies may overlook other important aspects, such as asset performance and condition. -

Periodic maintenance is scheduled after a definite time period, such as weekly, monthly, quarterly, or yearly. Predictive maintenance is based on the condition and performance of assets. It prevents recurrent maintenance by proactively fixing the equipment before it fails.