Preventative Gym Equipment Maintenance: Keep Machines Safe

Preventive gym equipment maintenance extends lifespan and prevents costly breakdowns. Learn how to schedule equipment maintenance for maximum efficiency.

In this article:

- Key Takeaways: Gym Equipment Maintenance

- The Benefits of Preventive Maintenance

- 1. Safety and Compliance

- 2. Cost Savings

- 3. Extends Lifespan

- 4. Reduces Downtime

- 5. Customer Retention

- Best Preventive Gym Equipment Maintenance Practices

- How to Schedule Preventive Maintenance for Gym Equipment?

- 1. Manage Your Inventory

- 2. Prioritize Equipment and Tasks

- 3. Check Ideal Preventive Maintenance Intervals

- 4. Schedule Maintenance

- 5. Monitor Schedules

- Schedule Your Gym Equipment Maintenance to Extend Its Lifespan

Fitness facilities invest heavily in their equipment, but what matters more is how well those machines are maintained. Proper gym equipment maintenance directly influences machine performance and, in turn, shapes the overall client experience.

Take a treadmill with a worn-out belt: it frustrates members, poses safety risks, and can even lead to liability issues for owners. That’s why preventive maintenance is essential.

From cleaning and lubrication to professional inspections, it keeps the machines running smoothly and safely. But what exactly does it involve, and how do you schedule it? This guide breaks it all down. Let’s dive in!

Key Takeaways: Gym Equipment Maintenance

- What it is: A proactive approach that involves regular cleaning, inspection, lubrication, and calibration of machines to prevent issues from piling up.

- What are the Benefits: It extends equipment lifespan, reduces costly breakdowns, and ensures members safety. Furthermore, it reduces the downtime which enhances member retention.

- How to Schedule Equipment Maintenance: Manage your inventory and prioritize equipment and tasks based on usage and condition. Check the manufacturer's guide for maintenance intervals, and schedule and monitor the maintenance tasks using digital tools.

The Benefits of Preventive Maintenance

Source: WorkTrek

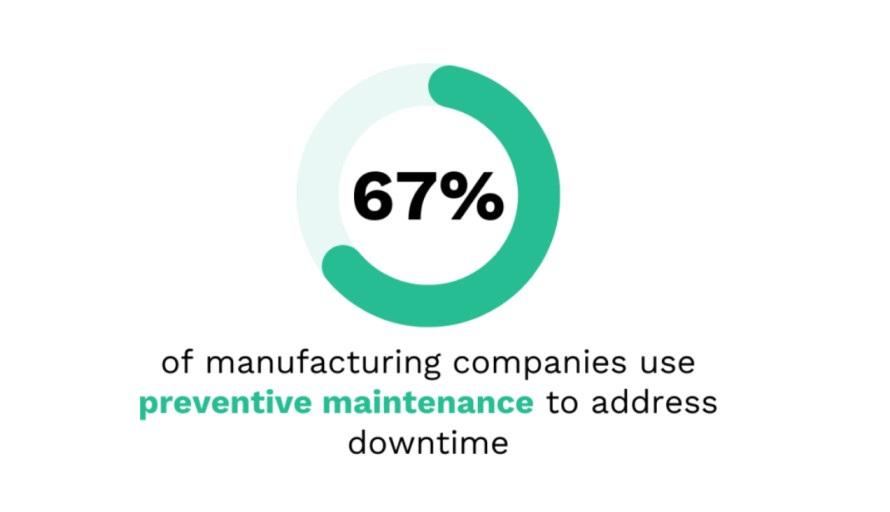

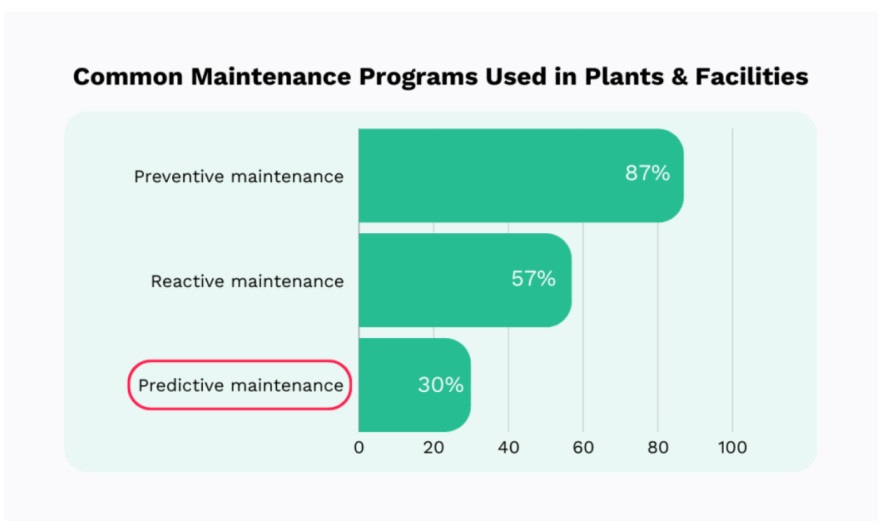

Running a gym is a costly business. From the initial investments to operational costs, the expenses can add up to a substantial amount. But that doesn’t mean you cut corners on equipment maintenance. According to research,

“Running a piece of equipment to the point of failure could cost up to 10 times as much as a regular maintenance program would.”

1. Safety and Compliance

Faulty machines, such as malfunctioning treadmills, frayed cables, or rusty bikes, can lead to serious accidents. According to the Consumer Product Safety Commission, over 24,000 treadmill-related injuries were reported in the US between 2005 and 2014.

Preventive maintenance minimizes these risks by catching issues early, before they turn into hazards. Regular inspections, lubrication, and part replacements keep machines safe for daily use.

It’s not just about member safety, either. Preventive maintenance also ensures compliance with industry regulations. Keeping detailed service logs proves that equipment is inspected on schedule, protecting gym owners from liability claims, fines, and lawsuits if an accident occurs.

2. Cost Savings

Every $1 spent on preventive maintenance saves $5 in repair costs down the line. A simple belt lubrication costs only a few dollars. However, delaying it may lead to a complete breakdown and push the repair cost up to $150-$300 for belt replacement.

Additionally, emergency breakdowns carry hidden costs. This includes emergency technician call-out fees, expedited shipping for parts, and lost revenue from unusable machines. Therefore, allocating a small budget for preventive maintenance can help avoid the financial shock of major repairs.

3. Extends Lifespan

High-quality gym equipment can last 10-15 years, while poorly-maintained machines often wear out in half the time. Regular cleaning, lubrication, and calibration reduce unnecessary wear and tear, which keeps your equipment reliable and extends its lifespan.

Besides extending the lifespan, it also ensures consistent performance. A well-maintained treadmill runs smoothly, whereas a neglected one frequently strains its motor and wears down belts. Preventive maintenance ensures your expensive assets are protected and delays the need for costly replacements.

4. Reduces Downtime

Nothing frustrates members more than walking into a gym and finding machines out of order. Downtime disrupts workout routines, damages your gym’s reputation, and drives members elsewhere.

Preventive maintenance reduces downtime and increases the machine performance by addressing small defects like squeaky belts or loose bolts before they escalate into major breakdowns. Proactive care keeps equipment running smoothly, ensures consistent performance, and delivers the uninterrupted service members expect.

5. Customer Retention

Members pay for a gym expecting it to be clean, safe, and fully functional. When members walk into a gym and find tread

mills running smoothly, weight machines properly calibrated, and bikes free of squeaks, they feel reassured. It confirms that their investment was worth it.

Conversely, a poorly-maintained gym, with broken machines, raises major red flags. Members may perceive it as mismanagement, safety risk, or even disregard for their well-being. As a result, they will cancel their membership at your gym and join a competitor.

Best Preventive Gym Equipment Maintenance Practices

Source: WorkTrek

A structured maintenance plan provides consistency and accountability, so no critical task is overlooked. This table outlines important preventive maintenance tasks, from daily upkeep to annual servicing, that will ensure your machines keep working efficiently.

| Schedule | Preventive Maintenance Tasks |

| Daily |

|

| Weekly |

|

| Monthly |

|

| Quarterly |

|

| Annually |

|

How to Schedule Preventive Maintenance for Gym Equipment?

By setting up a maintenance schedule, gyms can prevent their machines from breaking down and ensure smooth operations. Here’s how scheduling preventive maintenance works:

1. Manage Your Inventory

The first step in maintenance is knowing what you have. Start by documenting every piece of equipment in your facility and building an asset registry. Along with the name and quantity, you also need to include key details, such as:

- Purchase date

- Warranty information

- Serial number

- Manufacturer’s maintenance recommendations

- Service history

Keeping this information centralized, especially in a digital asset management system, allows you to track the health and status of each machine with ease.

This inventory becomes your reference gym equipment maintenance checklist that ensures no machine is missed during routine servicing. For gyms with multiple branches, a digital inventory works even better. It offers visibility across locations and helps owners make informed decisions about replacements and upgrades.

2. Prioritize Equipment and Tasks

Not all machines face the same level of stress. High-traffic equipment like treadmills, bikes, and ellipticals endure daily wear that free weights or resistance machines don’t. That’s why these should be first in line for preventive maintenance.

Cardio machines run for hours every day, handling repeated strain from multiple users. Ignoring early signs, like a frayed belt or uneven speed, can quickly turn into expensive repairs. By prioritizing heavily used machines and tailoring maintenance to usage, gyms save both time and money while keeping essential equipment consistently available.

3. Check Ideal Preventive Maintenance Intervals

Every piece of gym equipment comes with a manufacturer’s manual that outlines recommended maintenance intervals. While these guidelines provide an excellent starting point, they should be tailored to the usage patterns and conditions of your equipment. Historical maintenance data within your system can also help determine optimal servicing timelines.

Feedback from staff and members is equally valuable. If a treadmill slows down or a resistance machine starts squeaking, don’t wait for the next scheduled inspection; address it immediately. Acting early prevents small issues from becoming costly breakdowns.

4. Schedule Maintenance

Relying on manual scheduling methods, like spreadsheets and paper logs, often leads to missed tasks or inconsistent record-keeping. A smarter approach is to leverage digital scheduling tools and project management platforms.

| Pro Tip: Use scheduling tools with QR code integration. This allows the staff to scan equipment and instantly view its service history and scheduled maintenance. This saves time and effort while improving accuracy. |

These systems help assign maintenance tasks, send automated reminders, and create checklists to maintain consistency.

5. Monitor Schedules

Creating a schedule is just the starting point. A static schedule without performance tracking and review soon becomes outdated. The real value lies in ongoing monitoring and making continuous improvements.

By maintaining detailed service logs, you can track wear patterns, evaluate repair costs, and forecast maintenance intervals. These insights let you refine schedules and reduce recurring problems.

Schedule Your Gym Equipment Maintenance to Extend Its Lifespan

Preventive gym equipment maintenance is less about tightening bolts and more about shaping the overall experience of your gym members.

Rather than spending money on costly repairs and premature replacements, focus on regular inspections and preventive maintenance. This allows you to invest more in your gym growth, instead of repairing and replacing the worn-out machines.

To make it manageable, move beyond manual checklists. A digital asset management system can automate scheduling, track performance, and maintain service logs, ensuring no machine is overlooked and your equipment stays in top shape.

Frequently Asked Questions

-

Failing to clean regularly can cause sweat, dirt, and bacteria to build up on the gym equipment. This can lead to foul odors, health risks for the members, and reduced machine efficiency in the long run. When dirt and debris accumulate in the machine, it compromises the performance and increases the frequency of repairs.

-

Gym equipment manufacturers recommend using silicone-based lubricants for the best results. These products reduce friction without damaging belts or internal parts. White lithium grease also works well for machines with metal-to-metal connections.

-

Gym equipment like treadmills, ellipticals, and stationary bikes should be lubricated every three months. You can check the manufacturer’s manual for exact intervals according to your model and type. Regular lubrication reduces friction and ensures smoother operations, which helps gyms minimize costly repairs.