The Complete Guide to Fleet Inspection For Your Business

Fleet inspections are vital for business efficiency and safety. Learn about inspection schedules, best practices, and how Itefy can streamline the process

In this article:

- What is Fleet Inspection?

- Why is Fleet Inspection So Important?

- Driver Safety and Protection

- Preventive Maintenance

- Saves Operational Expenses

- Maintain Compliance

- Timings and Frequency of Fleet Inspections

- Pre-trip and Post-trip Inspection

- Monthly Inspection

- Quarterly/ Annual Inspection

- Post Accident Inspection

- Best Practices and Strategies For Fleet Inspection

- Create a Detailed Checklist

- Design Fleet Inspection SOPs and Protocols

- Real-Time Data & Telematics Integration

- Driver-Centric Inspection With Mobile Apps

- Automated Preventive Maintenance Schedule

- Inspection Records & Reporting

- Optimize Your Fleet Inspection With Itefy

A fleet is the lifeblood of any business, taking on the heavy lifting of operations. This is particularly true for industries like logistics, construction, and transportation, where vehicles are the powerhouse of daily activities. But what would you do if they suddenly stopped working during a critical operation?

That's where regular fleet inspection steps in, and keeps the vehicles in peak condition to maximize reliability, safety, and lifespan. So how would you achieve this? Let's look at what fleet inspection actually is, its importance for your business, and some of the best practices and strategies for successful implementation.

What is Fleet Inspection?

Fleet inspection is a structured process of thoroughly examining a company's vehicles to guarantee they are safe and functioning in optimal condition. It is a detailed check up performed by trained individuals. The aim of an inspection is to catch any potential problems before they lead to breakdowns or accidents. This includes inspecting crucial parts like brakes, tires, lights, steering, and safety gear.

Companies inspect their fleet to ensure that their vehicles meet all the required legal and safety standards. It's a proactive approach to vehicle maintenance, saving time and money.

Why is Fleet Inspection So Important?

Fleet inspections are critical for numerous reasons such as upholding safety standards, and protecting drivers and the public. Let's take a look at the key benefits of how they directly impact operational efficiency and long-term cost savings.

Driver Safety and Protection

A company’s top priority should always be the well-being of its drivers and staff. The FMCSA ( Federal Motor Carrier Safety Administration) highlights that faulty brakes cause almost 30% of truck accidents. Regular inspections allow mechanics to identify these issues early, preventing them from becoming a deadly threat.

Catching and fixing technical flaws promptly ensures your vehicles are safe to operate. This not only protects the drivers themselves but also reduces the risk of accidents that could harm other road users.

Image Source: Lookup A Plate

Preventive Maintenance

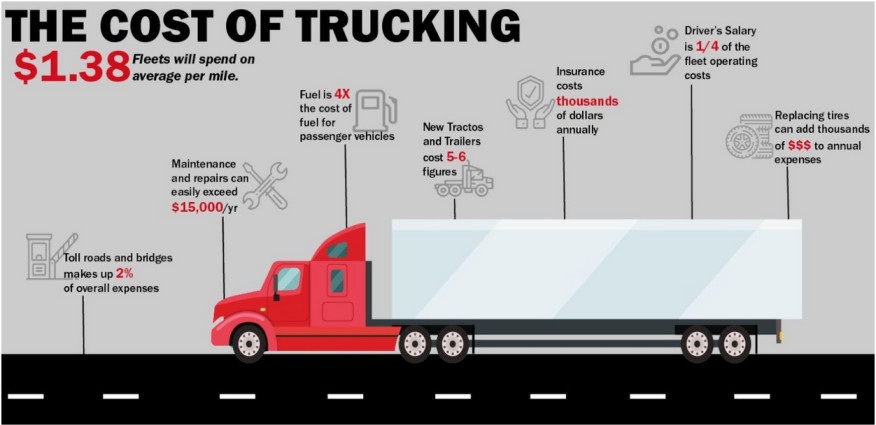

Preventive maintenance identifies minor issues before they escalate into major, expensive problems. Truck maintenance can easily exceed $15,000 per year when you factor in all the parts, such as the brakes, alternators, and wires. Addressing small concerns on time can help you save a lot of money in the long run.

For example, a mechanic might notice a slightly worn belt. Replacing it then is cheap. But if it snaps on the road, it could cause engine damage, costing thousands. Similarly, a small leak in a hose, easily fixed, could lead to engine overheating and a much bigger repair bill.

Image Source: IMI

Saves Operational Expenses

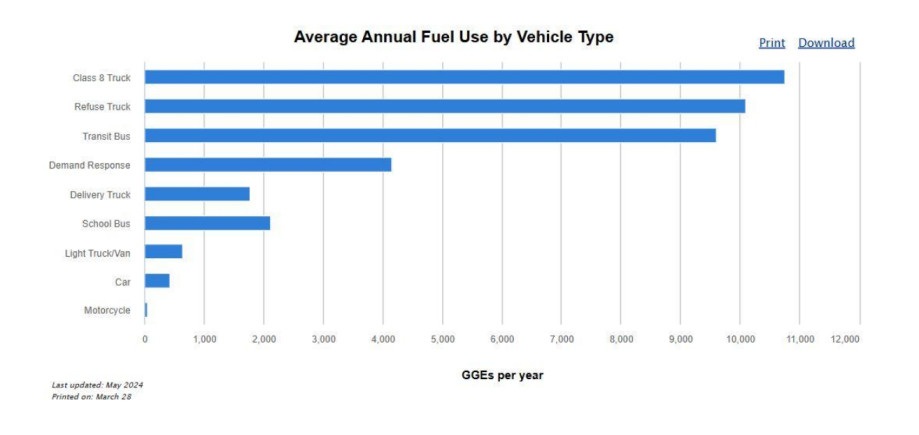

Regular fleet inspection has a direct impact on your business’s operating costs. Remember, commercial fleets are among the highest fuel-consuming vehicles ( up to 10,745 GGE per year). When vehicles are well-maintained, their engines run smoothly, tires are properly inflated, and everything works as it should. This means they use less fuel, saving you money and maintenance.

Furthermore, efficient vehicles produce fewer negative emissions. This helps you align with environmental regulations and avoid potential fines.

Image Source: Department of Energy

Maintain Compliance

Staying compliant is crucial for any fleet. Daily Vehicle Inspection Reports (DVIRs) are mandatory and maintain compliance with state and federal laws. Neglecting these reports might put you at the risk of substantial fines and mandated downtime, disrupting projects and schedules.

These inspections are not just paperwork but a critical safety measure. That is why regular fleet inspection is mandatory to avoid costly legal penalties by proving your commitment to vehicle safety.

Timings and Frequency of Fleet Inspections

Maintaining a fleet requires varied inspection strategies to ensure both immediate and long-term vehicle health. Here are a few recommendations for fleet inspection timelines:

Pre-trip and Post-trip Inspection

Pre-trip and post-trip inspections are essential daily routines for drivers. Before each journey, drivers must assess vehicle safety, checking for visible body damage, functioning lights, responsive steering, clear mirrors, and effective brakes.

Upon returning, a post-trip inspection verifies the vehicle’s state, if there are any new damages or fluid leaks. These daily checks are vital for identifying immediate safety concerns and preventing potential breakdowns.

Monthly Inspection

Every month, it's important to have a trained mechanic give your vehicles a more thorough check-up. They test the lights, brakes, and suspension to make sure they are in top condition. Any obvious issues, like leaks or excessive wear, are also assessed, along with tire condition for any wear or tear.

Quarterly/ Annual Inspection

Beyond monthly checks, quarterly or annual inspections provide an expert-level assessment of your fleet. Fleet mechanics will replace worn hoses, brackets, and filters, and thoroughly inspect brakes. They'll also handle essential tasks like greasing and lubrication, and assess engine and tire health.

These periodic inspections give you a clear picture of your fleet’s overall condition so you can plan for future vehicle replacements and maintain optimal performance.

Post Accident Inspection

Post-accident inspections determine the extent of damage after a collision. These examinations determine post-accident structural integrity, mechanical systems, and safety features. The goal is to identify hidden damage that might compromise future operations and assess repair needs.

Best Practices and Strategies For Fleet Inspection

Now that you understand the importance and frequency of fleet inspection, let's discuss some of the best practices and strategies. These methods will help you design and manage your own effective fleet inspection system.

Create a Detailed Checklist

The foundation of a robust fleet inspection system lies in thorough documentation. Start by evaluating each vehicle to determine its specific maintenance needs, and create a detailed checklist. Make sure nothing is overlooked and you have a standardized approach for inspections such as:

- Vehicle Maintenance: This includes a comprehensive check of fluid levels, tire pressure, brakes, air filters, hoses, belts, batteries, and the exhaust system.

- Vehicle Cleanliness: A checklist that covers interior and exterior cleaning, including vacuuming, chrome polishing, and window cleaning.

- Vehicle Safety: Prioritize safety by checking headlights, tail lights, safety equipment, steering, suspension, and any outstanding vehicle recalls.

Note: You might need to create specific guidelines for particular vehicles such as a truck maintenance checklist, a delivery van inspection, or specialized equipment checks for construction vehicles.

Design Fleet Inspection SOPs and Protocols

Designing clear protocols for vehicle inspection is necessary for maintaining consistency and accountability within the process. Start by outlining the fundamental SOPs that govern the entire inspection process, from scheduling to documentation.

- Responsibility and Task Identification: Specify who will be responsible for the inspection, whether it is an in-house team or an outsourced company. Assign specific tasks and timelines to individual team members for a transparent workflow.

- Inspection Scheduling: Develop a specific schedule that details when each vehicle requires specific maintenance tasks. Using fleet management software or other technology tools can streamline the entire process.

- Property Identification Numbers: Assign a unique property identification number to each vehicle and label it with relevant information such as the vehicle's make, model, year, and assigned department, for accurate tracking and record-keeping.

Real-Time Data & Telematics Integration

A successful fleet inspection system relies on real-time data. Equipment management software can easily integrate with fleet telematics and offer a comprehensive view of vehicle health. These systems utilize barcodes, RFID, and GPS systems and provide instant updates on vehicle location, speed, and crucial operational parameters.

These integrations facilitate trend analysis, predict potential issues, and help with proactive maintenance schedules. Immediate alerts for critical defects minimize downtime and enable rapid information regarding fleet safety.

Driver-Centric Inspection With Mobile Apps

Empower your drivers through mobile apps to actively participate in fleet inspection. They can instantly report defects, attach photos, and receive maintenance notifications. This creates a direct communication channel between drivers and maintenance teams.

Also, all relevant team members can add any property identification code in the app and get quick access to detailed vehicle history, maintenance schedules, and inspection records. This will ensure that everyone is working with the most up-to-date information.

Automated Preventive Maintenance Schedule

An equipment management software like Itefy helps you set automated preventative maintenance schedules based on mileage, usage, or time intervals. This system generates timely reminders for scheduled inspections and maintenance.

This proactive maintenance approach reduces repair costs and minimizes unexpected downtime during critical operational periods.

Inspection Records & Reporting

Maintaining accurate inspection records helps fleet managers make informed and data-driven decisions. Equipment management software automates this, storing all inspection data and building detailed vehicle maintenance histories.

These records are linked by individual property ID labels and enable proactive maintenance strategies based on trend analysis. You can generate reports based on real-time data decisions on maintenance schedules, vehicle replacements, and cost optimization.

Optimize Your Fleet Inspection With Itefy

Fleet inspection is far more than a mere fault check. It is a strategic investment in your business's longevity and efficiency. A well-planned inspection strategy minimizes downtime, enhances safety, and significantly reduces operational costs. It is a safety net that lets your business operations keep running smoothly.

To optimize your fleet management and inspection process, choose Itefy. Its outstanding features like equipment management, maintenance tracking, live stats, a user-friendly mobile app, and a real-time data dashboard—empower you with complete control. Switch to Itefy and let your fleet operate at peak performance.

Frequently Asked Questions

-

Checklists should be reviewed and updated at least annually, or immediately following any regulatory changes, the introduction of new vehicle models, or significant changes in operational demands.

-

Prioritize safety by immediately taking the vehicle out of service. Document the issue thoroughly, and communicate with maintenance teams for rapid repair scheduling. Use fleet management software to track repair progress and find replacement vehicles.

-

Start with hands-on training sessions, clear documentation, and ongoing support. You can also create video tutorials and offer short training courses to the relevant team members such as drivers and mechanics.