A Step-by-Step Guide to Creating a Fleet Maintenance Checklist

Learn how to create a clear and effective fleet maintenance checklist with this easy step-by-step guide. Keep your vehicles safe, reliable, and road-ready.

In this article:

- Key Components of an Effective Fleet Maintenance Checklist

- 1. Daily Inspections for Catching Small Issues

- 2. Monthly Maintenance Tasks to Keep Essentials in Check

- Step-by-Step Guide to Creating Your Fleet Maintenance Checklist

- 1. Assess Your Fleet Needs

- 2. Consult the Manufacturer Guidelines

- 3. Incorporate Regulatory Requirements

- 4. Customize Tasks Based on Vehicle Type and Usage

- 5. Implement a Tracking and Scheduling System

- 6. Establish Preventive Maintenance Schedules

- 7. Train Personnel and Promote Accountability

- Master Your Fleet Checklist Strategy with Itefy

With unplanned vehicle downtime costing fleets as much as $760 per day/vehicle, it’s important for companies to keep that at a minimum. This is where a fleet checklist comes in handy. Such a checklist helps identify potential issues before they escalate.

It ensures that the fleet remains operational and safe. However, this checklist isn’t just about preventing breakdowns—it’s about ensuring safety, optimizing efficiency, and safeguarding your bottom line.

In this guide, we’ll explain how to create an effective fleet maintenance checklist and reduce vehicle downtime.

Source: Chevin Fleet Solutions

Key Components of an Effective Fleet Maintenance Checklist

An effective fleet and truck maintenance checklist is more than a to-do list. Here are the essential components you must include to make your checklist truly effective:

1. Daily Inspections for Catching Small Issues

Daily checks are the first line of defense. They help drivers and maintenance teams spot problems early, before they become expensive or dangerous.

The things you should include in your daily checklist are:

- Tire pressure and tread wear

- Oil, coolant, and fluid levels

- Brake function and responsiveness

- Lights (headlights, brake lights, indicators)

- Horn, wipers, and mirrors

- Leaks under the vehicle

- Dashboard warning lights

- Safety equipment (first aid kits, fire extinguishers)

2. Monthly Maintenance Tasks to Keep Essentials in Check

Monthly tasks are just as essential as the daily checks. They help maintain vehicle efficiency, compliance, and roadworthiness. Here’s what you should include in your monthly fleet checklist:

- Checking battery health

- Engine diagnostics

- Transmission fluid level

- Fuel system inspection

- Detailed brake checks

- Alignment and suspension

Step-by-Step Guide to Creating Your Fleet Maintenance Checklist

Here’s a structured approach that you can follow to develop a fleet checklist that works according to your specific needs.

1. Assess Your Fleet Needs

Begin by evaluating the unique requirements of your fleet, such as:

- Inventory Analysis: Compile detailed information on each vehicle, including make, model, year, mileage, and usage patterns. This data will serve as the foundation for personalized maintenance schedules.

- Operational Demands: Analyze how each vehicle is being utilized. Consider factors like load capacity, driving conditions, and frequency of use. If any vehicle is subjected to heavy loads or harsh environments, it may require more frequent maintenance.

- Maintenance History: Review past equipment maintenance logs to identify recurring issues or patterns. Recognizing common problems can help in preemptively addressing them and reducing unexpected breakdowns.

This will allow you to lay the groundwork for a maintenance plan that aligns with your fleet’s specific demands.

2. Consult the Manufacturer Guidelines

After assessing where your fleet is lacking, read the manufacturer’s guidelines. Manufacturers usually provide specific maintenance recommendations to ensure your fleet works at its best.

Don’t forget to follow these guidelines and adhere to the suggested intervals for oil changes, tire rotations, and other services. Also, be aware of the expected lifespan of critical components like timing belts or brake pads.

If you follow these guidelines properly, you can prevent premature wear and costly repairs.

3. Incorporate Regulatory Requirements

Source: Etactics

Non-compliance with vehicle safety regulations can result in fines exceeding $15,000 per violation and even more. That’s why it’s mandatory to comply with the local, state, and federal regulations, including:

- Safety Standards: Ensure that all vehicles meet mandated safety inspection criteria, which may include checks on the braking system, lighting, and emissions.

- Environmental Regulations: Adhere to emissions and waste disposal guidelines to minimize environmental impact and avoid potential fines.

- Record-Keeping: Maintain meticulous records of all maintenance activities, inspections, and repairs. Detailed documentation is often required during asset management audits and can serve as evidence of compliance.

4. Customize Tasks Based on Vehicle Type and Usage

Different vehicles have unique maintenance needs that are key to ensuring your fleet's efficiency. Here’s the list of what you should consider:

- Vehicle Classification: Differentiate maintenance tasks between light-duty vehicles, heavy-duty trucks, and specialized equipment. Each category should have distinct service requirements.

- Usage Intensity: Adjust maintenance frequency based on how intensively a vehicle is used.

- Special Features: Account for vehicles with unique features, such as refrigeration units or hydraulic lifts.

5. Implement a Tracking and Scheduling System

The best way to keep track of all your vehicles is to use fleet management software like Itefy. It will help you schedule services, track completed tasks, and set reminders for upcoming maintenance.

Moreover, a standardized method for recording maintenance activities, including details like date, service performed, parts replaced, and technician notes, should be established. Remember to clearly define roles and responsibilities within your team.

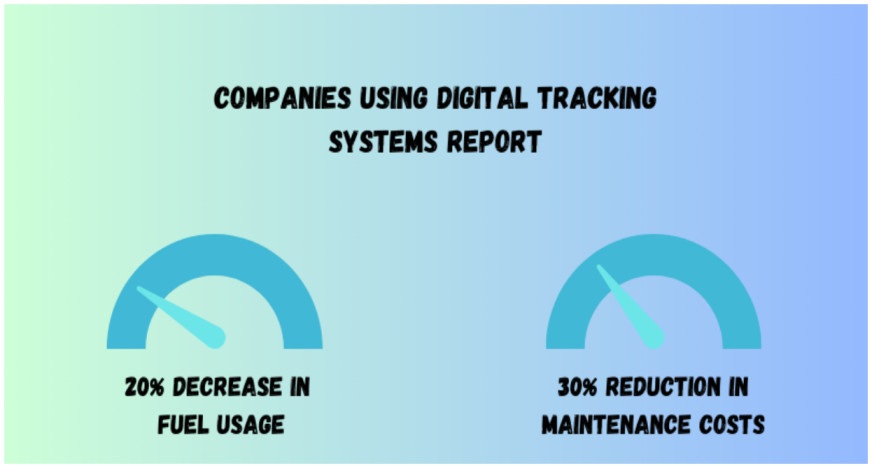

According to research, companies using digital tracking systems report a 20% decrease in fuel usage and a 30% reduction in maintenance costs.

Source: Global Growth Insights

6. Establish Preventive Maintenance Schedules

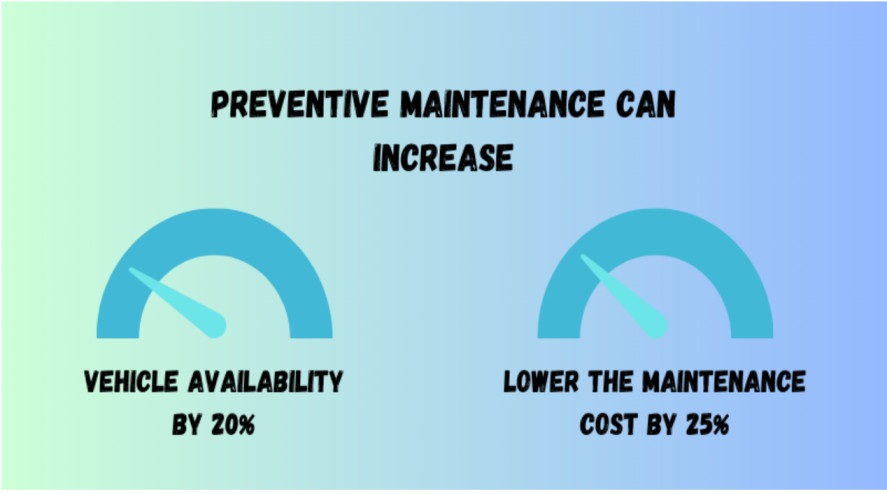

For your fleet checklist to be effective, you need a preventive maintenance schedule, which will help avoid costly repairs and extend vehicle lifespan. Studies show that predictive and preventive maintenance can increase vehicle availability by 20% and lower the maintenance cost by up to one-fourth.

Source: NextGen Invent

Alt Text: Impact of preventive maintenance on fleets.

Therefore, schedule regular inspections to identify and address minor issues before they escalate. Also, determine service intervals based on manufacturer recommendations, usage patterns, and historical data.

By proactively scheduling maintenance, you can ensure that vehicles remain in optimal condition.

7. Train Personnel and Promote Accountability

In the end, you need to train your team, as it’s essential for successfully implementing a maintenance plan. Provide regular training sessions for drivers and maintenance staff on best practices, safety protocols, and the importance of routine checks.

You can also provide a checklist sheet with all the essential routine checks so your team can easily tick-mark all of them. This way, they won’t have to memorize everything; they can just read from the sheet, examine it, and check and mark it.

Master Your Fleet Checklist Strategy with Itefy

Creating and maintaining a fleet checklist isn’t just another task—it’s a proactive move that protects your assets, ensures safety, minimizes downtime, and keeps your operations running smoothly.

However, managing it all manually, especially with a growing fleet, can be overwhelming. This is where Itefy’s equipment and asset management software comes in handy. It can help companies of all sizes streamline maintenance, track usage, and automate reservations—right from any device.

Start your free 14-day trial with no credit card required!

Frequently Asked Questions

-

If a driver misses a maintenance check or doesn’t go through it intentionally, follow up immediately. Also, investigate why it was missed and reschedule the task. Repeated misses should be addressed with training or accountability steps to prevent future lapses.

-

No, electric and gas vehicles have different components. EVs need checks for batteries and software, while gas vehicles require engine and fluid checks. So, you need to customize your checklist based on vehicle type.

-

Update it every 6–12 months or when you add new vehicles, change routes, or see new issues. Make sure to keep your checklist up-to-date as it reflects your fleet’s actual needs and avoids gaps in maintenance.