Fleet Management Cost Analysis: Things You Need To Know

A comprehensive fleet management cost analysis is essential to maximize your fleet's potential . Let's understand what it is and how it helps you optimize costs.

In this article:

- What are Fleet Management Costs?

- Types of Costs in Fleet Management

- 1. Fixed Costs

- 2. Variable Costs

- Fleet Management Cost Analysis

- 1. Total Cost of Ownership (TCO)

- 2. Cost Per Mile (CPM)

- Reducing Fleet Costs - A Practical Guide

- 1. Vehicle Selection and Maintenance

- 2. Fuel-Efficient Driving Practices

- 3. Better Routing and Scheduling

- 4. Use Fleet Management Software

- Take Action With Itefy's Fleet Management Solutions

Managing a fleet is much more than scheduling driver shifts and keeping vehicles on the road. Any company relying on a fleet to conduct its business must do a thorough fleet management cost analysis. How many trucks should be on the road? How many drivers should you hire? What about maintenance and repair costs?

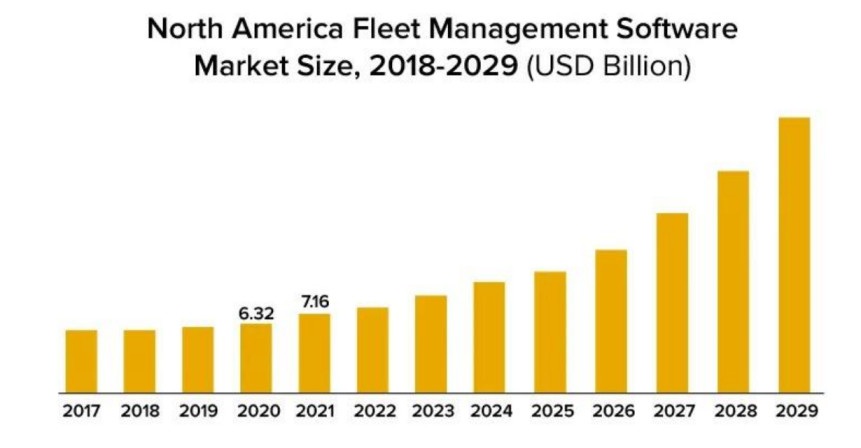

Figuring out all these answers is tricky enough for a small fleet. However, the picture becomes incredibly complex when you have a giant fleet and a team to match it. That is why it is crucial to manage and optimize fleet costs. It is also worth mentioning that the fleet management market is growing rapidly and is expected to reach $300 billion by 2034.

So, what is fleet management cost analysis, and what are some of its essential aspects you should know about?

What are Fleet Management Costs?

Before we move any further, let's answer the primary question first.

Fleet management costs mean the money you spend on maintaining a fleet of vehicles. These usually include the following:

- The major costs are fuel, operational costs, driver salaries, and equipment.

- Companies also deploy modern tracking technology, such as GPS or telematics. These technologies help replan routes, minimize fuel costs, reduce wear and tear, and more.

- Administrative costs, such as taxes, insurance, and vehicle registration.

For 84% of fleet managers, cost savings is the most critical determinant of success.

Add all of these up, and you are looking at a hefty bill that can be hard to afford. That's where fleet management cost analysis comes to the rescue. Let's discuss the mechanisms that enable it to alleviate your financial burden.

Types of Costs in Fleet Management

Fleet management costs involve multiple expenses that can be divided into two general categories:

1. Fixed Costs

Also known as overheads, fixed costs usually cover monthly payments and aren't affected by time or distance. They make budgeting and forecasting easier for companies.

Some fixed costs examples are:

- Insurance

- Trucks payments

- Permits and licenses

- Office rents

- Legal fees

2. Variable Costs

Variable costs are the opposite of fixed costs: they change based on various factors, such as mileage, work volume, parts used, and more. Given their impact on a company's bottom line, variable costs usually necessitate a comprehensive cost analysis.

Following are some examples of variable costs:

- Tires

- Fuel

- Fleet maintenance costs

- Legal violations and accidents

- Food and lodging

Fleet Management Cost Analysis

Maintaining and controlling costs can be a significant challenge for a company managing a large fleet of vehicles. Implementing cost controls requires a systematic fleet analysis that works for your business. Fleet automation software can help by offering real-time, accurate expense tracking. It identifies areas where you can save money and provide valuable insights into your fleet.

The fleet management cost analysis usually revolves around two factors, namely Total Cost of Ownership (TCO) and Cost Per Mile (CPM), which we'll discuss here.

1. Total Cost of Ownership (TCO)

Total cost of ownership is a critical component of any fleet management cost analysis. It deals with the actual cost of your fleet by calculating the difference between asset purchase prices and fleet management costs. TCO calculations can help companies adjust fleet sizes, optimize maintenance schedules, and decide the best vehicle replacement timing.

TCO = Initial cost – (Operation cost + Maintenance + Downtime + Production) – Remaining Value

Let's unpack this formula:

- Initial cost: The upfront vehicle price, whether purchased or leased.

- Operation cost: Expenses for running the fleet, such as licensing, fuel usage, driver compensation, and vehicle administration.

- Maintenance: Recurring expenses to keep vehicles in top shape, including repairs, downtime, and upkeep.

- Production: How much revenue can the fleet generate?

- Remaining value: The depreciation in vehicle value due to age and wear.

Companies with smaller fleets are advised to use specific fleet data to calculate TCO. In these cases, using the standard industry data to calculate TCO skews the results. It doesn't paint an accurate picture of your fleet.

2. Cost Per Mile (CPM)

Cost Per Mile (CPM) calculates the expense of driving a vehicle one mile. Its formula is:

CPM = (Fixed expenses + Variable expenses) / Total number of miles traveled

This formula adds all the expenses, including fixed and variable, and divides them by the miles traveled to calculate CPM. Here's how CPM evaluation helps your company:

- Shows the financial efficiency of each vehicle.

- Helps analyze current routes.

- Shows how much cost is associated with vehicle usage.

- Helps drivers improve their performance.

Reducing Fleet Costs - A Practical Guide

Once you have performed a comprehensive fleet management cost analysis, it is time to consider how you can reduce those costs. It is arguably the most significant concern for fleet managers, so let's address it.

1. Vehicle Selection and Maintenance

The best way to cut costs is to select suitable vehicles. Fleet managers should pick vehicles perfectly suited for the intended purpose and ensure they have the required functionalities. For instance, if the vehicle is used in tight urban spaces, it should be small and fuel-efficient instead of a large vehicle that consumes extra fuel.

Regular maintenance is also crucial to minimize repairs and fuel consumption. Conduct regular vehicle inspections to identify issues before they need full-blown repairs.

2. Fuel-Efficient Driving Practices

Promoting fuel-efficient driving practices can reduce fuel consumption. Some techniques drivers can be taught regarding fuel consumption are maintaining a consistent speed, smooth acceleration and braking, and avoiding unnecessary idling. Similarly, you should equip vehicles with fuel-efficient technologies, including low-resistance tires, sleeper roof fairings, chassis skirts, cab extenders, and the like.

3. Better Routing and Scheduling

Improved routing and scheduling can significantly affect fuel and maintenance costs. Today, fleet managers can use advanced software programs to plan the most efficient routes according to weather, traffic congestion, road conditions, and more. GPS tracking can also provide real-time information about your fleet, helping you change routes instantly.

4. Use Fleet Management Software

Modern software has significantly reduced the burden of fleet managers through efficient scheduling and planning. By providing real-time data on vehicle performance, fuel consumption, schedules, and maintenance, managers can instantly identify areas of improvement and make their fleets more efficient. For instance, the software can tell you if a vehicle should be replaced or repaired based on poor performance. It can also help you optimize routes and re-sequence or consolidate deliveries.

The North American fleet management software market is growing rapidly.

Take Action With Itefy's Fleet Management Solutions

Fleet management cost analysis can be complex, involving everything from vehicle tracking to optimizing resources. Thankfully, Itefy's Transportation Fleet Management Software can make it so much easier. Our solution ensures an excellent return on investment (ROI), bringing transparency and efficiency to the existing fleet. We help you optimize your fleet resources, prevent unexpected breakdowns, minimize costs, schedule effectively, and streamline your inventory management system.

So, are you ready to save money through optimal fleet management and analysis? Just spend 5 minutes getting started with Itefy, and you can use it for free for the first 14 days.