Manufacturing Inventory Management: Types, Importance, and Best Strategies

Confused about manufacturing inventory management? Read this guide to learn it all, from its importance to the best strategies to the most efficient tools.

In this article:

- What is Manufacturing Inventory Management?

- Manufacturing Inventory Example and Types

- 1. Raw Materials

- 2. Work-in-Progress (WIP)

- 3. Finished Goods

- 4. Maintenance, Repair, Orders (MRO)

- Importance of Manufacturing Inventory Management

- 1. Operational Efficiency

- 2. Cost Reduction and Profit Maximization

- 3. Quality Assurance and Customer Satisfaction

- 4. Risk Management

- Best Strategies for Manufacturing Inventory Management

- 1. Just-in-Time Inventory Management (JIT)

- 2. First In, First Out (FIFO)

- 3. Last In, First Out (LIFO)

- 4. Economic Order Quantity (EOQ)

- 5. Weighted Average Cost (WAC)

- 6. Cycle Counting

- 7. ABC Inventory Analysis

- 8. Cloud-Based/Digital Inventory Management

- Manufacturing Inventory Management Tools

- 1. Itefy Asset Management System

- 2. Zoho Inventory

- 3. SOS Inventory

- Conclusion

The most important thing for a manufacturer is to produce high-quality products and take them to customers timely while maintaining healthy profit margins. It sounds simple, but there is a lot of complexity beneath the surface.

From ordering raw materials to turning them into final products, manufacturing inventory management is needed to monitor supply chains and reduce manufacturing costs.

The name does sound complex, but don't worry. We have prepared a detailed guide that will give you manufacturing inventory examples, the best strategies, and the tools you can use to take its management to the next level.

What is Manufacturing Inventory Management?

Manufacturing inventory management refers to the process in which a manufacturer monitors and manages raw materials, components, and finished products. This process is important to ensure production runs smoothly without any major issues. To achieve this, several elements work together, such as forecasts, orders, storage, and regular inventory audits.

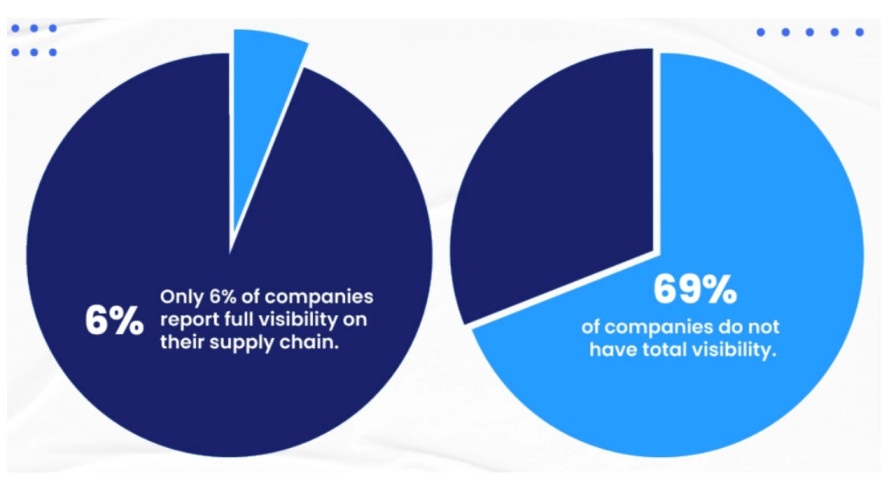

A large number of companies lack complete supply chain visibility.

Since management for manufacturing involves multiple aspects, from forecasting to final product storage, manufacturing inventory management works perfectly only when various departments coordinate. Today, organizations use manufacturing inventory tracking software to monitor finer details and coordinate seamlessly among multiple departments.

According to McKinsey & Company, supply chain disruptions occur every 3.7 years and last a month longer on average. This points to the importance of inventory management, as it lets organizations manage supply chains and prepare for shocks.

Manufacturing Inventory Example and Types

Following are the different types and examples of inventory that manufacturers usually deal with. We’ll elaborate on them using the example of a car manufacturer.

1. Raw Materials

Raw materials are what a business uses to produce certain goods. A company can produce raw materials in-house or procure them from other parties. They are usually understood in two categories, for manufacturing inventory management:

- Direct raw materials

- Indirect raw materials

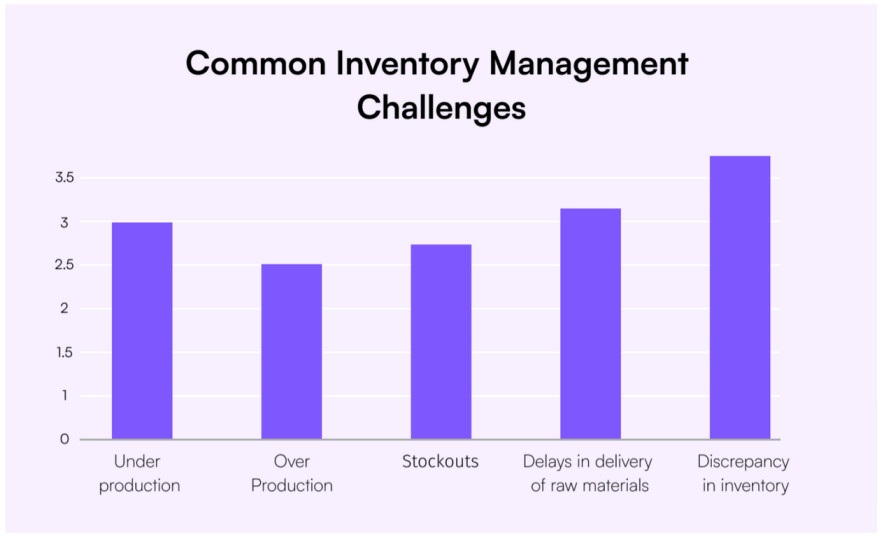

Delay in the delivery of raw materials is one of the biggest challenges for manufacturers.

a). Direct Raw Materials

Direct raw materials are used in the final stock manufacturing phase and are calculated on a per-unit or per-batch basis. Examples include wood used in furniture or steel used in car manufacturing.

b). Indirect Raw Materials

Indirect raw materials, such as lubricants, are not part of the final product. It is harder to trace them to specific batches or units, as they only support the manufacturing process instead of becoming a major part of them. For instance, safety gear used during the production process are indirect raw materials.

2. Work-in-Progress (WIP)

The WIP inventory refers to the materials you use to produce a certain product, but the final product is yet to be manufactured. It involves both direct and indirect raw materials, since the manufacturing process is ongoing.

Continuing with our example of a car manufacturer, suppose it takes one week to produce one car. Once the manufacturer starts shaping the steel and cutting the class, they cease to be raw materials and are now part of the WIP inventory until the car is fully manufactured.

3. Finished Goods

Finished goods inventory includes all items or products that have been fully manufactured and are ready to be sold. However, it could mean different things for different organizations depending upon the model they follow.

If they use a make-to-order model, the finished product can be shipped after it’s fully manufactured. On the other hand, following the make-to-store or make-to-stock model means the company will stock the product until an order comes through. Whichever model you choose between these two, it is clear that keeping track of your inventory is pretty straightforward.

4. Maintenance, Repair, Orders (MRO)

The MRO inventory is crucial to keep operations running by maintaining and repairing equipment through an equipment maintenance log. It is strictly meant to be used within an organization and is never meant for sales unless an organization acquires new equipment.

For instance, the hypothetical car manufacturer we use as an example keeps its workspaces very clean. A team of janitors does the cleaning every day by using vacuum cleaners, cleaning liquids, and related supplies. Similarly, the maintenance and repair team requires a special set of tools for maintenance tasks. It is obvious that none of this equipment is up for sale because it is used by the company in essential internal operations.

Importance of Manufacturing Inventory Management

Let’s look at why industrial inventory management is crucial to the success of any manufacturer and requires adequate attention.

1. Operational Efficiency

Quality manufacturing inventory management is directly linked to an improvement in operational efficiency. Manufacturers can ensure a continuous and steady flow of products by managing stock levels and streamlining manufacturing processes. Given this coordination, companies can avoid major manufacturing bottlenecks in the form of downtime and production delays.

Using advanced software, manufacturers can keep tabs on inventory levels in real-time, which helps them adjust their production schedule and capacity to handle changing customer demand and industry requirements. Not only does it help minimize shortages, but also prevents surpluses.

Real-time tracking also enables timely and seamless communication among various departments, so everyone knows what is expected of them, the target inventory levels, and the overall production goals.

2. Cost Reduction and Profit Maximization

You can reduce costs and increase profits by taking a strategic approach to inventory management. Cost reduction measures can apply to the following:

- Storage

- Insurance

- Taxes

- Holding costs

Similarly, well-thought-out inventory management prevents both overproduction and surpluses, which are financially burdensome. The former is burdensome because it uses more raw materials, financial resources, and space, and the latter is problematic due to lost sales.

Robust inventory management also results in a consistent turnover, which is crucial to a company’s financial health. It means no capital is tied up in unoptimized production, and manufacturing follows the supply and demand law.

3. Quality Assurance and Customer Satisfaction

Quality control and customer satisfaction have a close relationship with accurate inventory management. When everything is optimized, from ordering raw materials, companies can get the highest quality of raw materials at the best possible prices. It leads to a higher product quality compared to other manufacturers.

Similarly, inventory management ensures that companies can keep up with customer demands. With accurate numbers on production capacity and inventory levels, issuing delivery timelines and sticking to them becomes easier. Ultimately, it means winning over customers’ trust and increasing sales.

4. Risk Management

We live in a globalized economy where disruptions in one part of the world can affect the whole supply chain. Therefore, manufacturers must stay vigilant and adopt robust inventory management tools and practices that shield them from these risks. A flexible plan means swift adaptation to changing circumstances, reducing their impact on the company’s health.

Best Strategies for Manufacturing Inventory Management

Accurate manufacturing inventory management is critical to keep production lines and supply chains healthy. With that said, the way a business approaches inventory management depends upon its size, goals, the type of industry and products it sells, and the like.

The following are the most common strategies or approaches businesses adapt to handle production and inventory management, so let’s explore them.

1. Just-in-Time Inventory Management (JIT)

The manufacturer only has what’s needed to meet current consumer demands, with very little to no future stocks. It costs less, but there is also a catch: any disruption in the supply chain can severely hamper production.

2. First In, First Out (FIFO)

The oldest inventory is used first in the production process. This strategy comes in really handy for companies using raw materials with expiry dates, such as the food industry, pharmaceuticals, and more.

3. Last In, First Out (LIFO)

The opposite of FIFO, LIFO involves using the latest inventory first. Companies adopt this to reduce tax burden because the cost of goods sold is calculated based on the cost of the most recent purchases. Since the latest inventory is usually more expensive, it results in a lower taxable income.

4. Economic Order Quantity (EOQ)

EOQ is a mathematical model companies use to determine the precise inventory required for production to minimize costs and prevent stock overflows. The factors used in calculating it are annual demand, ordering cost, and holding cost.

5. Weighted Average Cost (WAC)

This strategy involves taking the average cost of the overall inventory instead of calculating the cost for each item. It takes a streamlined cost approach to the various units of the same items purchased at different times. It helps companies smooth out the price fluctuations in the cost of goods sold.

6. Cycle Counting

Cycle counting deals with the audit part of inventory management involves physically counting small portions of inventory regularly instead of counting all at once. It provides a more reliable, (although a bit slower) inventory tracking method.

7. ABC Inventory Analysis

This approach categorizes inventory based on its value to the manufacturer. The items in the A category are most valuable, followed by those in B and C. When ordering and stocking, the manufacturer prioritizes the inventory in the A category.

8. Cloud-Based/Digital Inventory Management

Cloud-based inventory management combines the utility of all previous manufacturing inventory systems in one place and provides an advanced tracking platform accessible 24/7. Optimizing business operations with fixed asset management software means continuous inventory tracking on the go, detailed statistics on a dashboard, repair and maintenance alerts, and many other features.

Manufacturing Inventory Management Tools

Since organizations today use advanced software to track manufacturing inventory, let’s briefly touch upon the top three manufacturing inventory management tools available today.

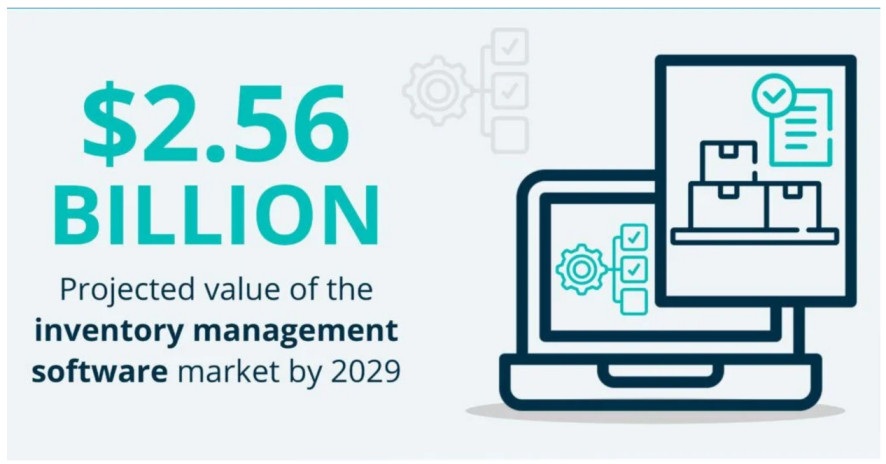

The inventory management software market is projected to grow significantly in the coming years.

1. Itefy Asset Management System

Pricing

- Basic: $33/mo – paid yearly

- Startup: $83/mo – paid yearly

- Business: $149/mo – paid yearly

- Enterprise: $359/mo – paid yearly

Itefy is a leading name in the software industry, assisting numerous successful organizations in managing their inventory. Some of its best features for monitoring stock manufacturing include the following:

- Add equipment with an advanced mobile app or on the webpage.

- Multiply the same equipment with autonumbering.

- Detailed planning and scheduling for equipment usage.

- Regular reservations for maintenance, refills, and the like.

- Live inventory and equipment statistics on a simple and comprehensive dashboard.

- Available on all devices with regular updates and quality customer care.

2. Zoho Inventory

Pricing

- Standard: $29/mo – billed annually

- Professional: $79/mo – billed annually

- Premium: $129/mo – billed annually

- Enterprise: $249/mo – billed annually

Zoho Inventory is another capable inventory management software that is available as an app on both Google Play Store and App Store. It offers personalized workflows where you can trigger custom actions when an invoice is overdue. With a special feature called Webhooks, you can trigger actions or work flows in third party apps.

Here are some additional features of Zoho Inventory:

- Supplier and purchase order management

- Inventory optimization

- Serialized inventory tracking

- Batch and expiry date tracking

3. SOS Inventory

Pricing

You can add additional users for $25 each for all plans.

- Companion (2 users): $64.95/mo

- Plus (3 users): $129.95/mo

- Pro (5 users): $179.95/mo

SOS Inventory is a cloud-based tool used mostly by small and medium-sized businesses. It is well-integrated with multiple e-commerce shopping carts and vendors, such as Shopify, PayPal, Ship station, and many others. SOS Inventory also offers a free trial where you do not need to submit credit card information.

Let’s look at some of its prominent features:

- Manufacturing management

- Vendor management

- Mobile access

- Barcode scanning

Conclusion

Manufacturing inventory management is critical for any company to streamline its operations and optimize its resource usage. While there are several strategies that companies have adopted over the years, digital inventory management takes the lead today because of its features and efficiency.

If you also want to take maximum advantage of this digital revolution in inventory management, look no further than Itefy’s manufacturing inventory software. It has all the advanced features you want, such as live statistics, on-the-go tracking, smartphone compatibility, timely updates, and much more.

On top of that, it offers everything at reasonable prices, making an advanced system accessible to everyone. So, try our free trial today and upgrade after 14 days.

Frequently Asked Questions

-

The four major types of inventory management systems include the following:

Cloud-Based

Just-in-Time (JIT)

ABC Analysis

First In, First Out (FIFO) -

The five stages of inventory management are:

Demand forecasting

Restocking

Order processing

Storage

Analysis and reporting -

You can organize manufacturing inventory by using an inventory management system like the one provided by Itefy. With its advanced features, there is very little manual work, and it keeps you updated with everything in one place.