How an Equipment Maintenance Log Improves Equipment Reliability

Have you ever faced a situation where your equipment broke down at the worst possible time? You need an equipment maintenance log to get rid of it forever.

In this article:

- What is an Equipment Maintenance Log?

- Types of Equipment Maintenance Log

- What’s Included in an Equipment Maintenance Log?

- Who is Responsible for Equipment Maintenance

- Equipment Maintenance Log Example

- Five Benefits of Equipment Maintenance Logs

- Minimizes Repair Costs

- Validates Warranty Claims

- Improves Workplace Safety

- Enhances Accountability

- Improves the Resale Value

- Best Practices for Equipment Maintenance Log

- Consistency in Logging

- Detailed Record-Keeping

- Using CMMS Software for Maintenance Logs

- Step-by-Step Guide to Creating an Equipment Maintenance Log

- Step #1: Identify the Equipment

- Step #2: Choose a Log Format

- Step #3: Set Up the Log

- Step #4: Implement Consistent Record-Keeping

- Step #5: Review and Update Regularly

- Common Challenges and Solutions in Equipment Maintenance Logging

- Challenges in Maintaining Logs

- Incomplete Entries

- Missed Service Updates

- Loss of Paper Logs

- Solutions Using Digital Tools

- Automated Logging

- Scheduled Maintenance Alerts

- Digital Storage and Accessibility

- Enhanced Data Accuracy

- Manage Your Equipment Maintenance Logs with Itefy

Have you ever encountered a situation where your equipment broke down at the worst possible time because it hadn't been maintained for months? It's indeed frustrating and can lead to costly downtime.

This is where an equipment maintenance log becomes an invaluable solution. It’s basically a record-keeping system for tracking the maintenance history of machinery or equipment. It creates documents of all maintenance activities, including inspections, repairs, servicing, and other upkeep tasks.

By keeping maintenance reports, you can predict when your machinery needs repair or replacement. This reduces unexpected downtimes, extends the life of your equipment, and improves efficiency.

Now, let’s dig into this topic in detail and understand every aspect of the equipment maintenance log.

Cost incurred due to unplanned downtime.

What is an Equipment Maintenance Log?

By definition, an equipment maintenance log is a systematic record-keeping tool that tracks the servicing, repairs, and upkeep of machinery and equipment over time. It’s like a central headquarters with all the information regarding equipment activities such as routine inspections, dates of maintenance, emergency repairs, and so forth.

The most important role of a maintenance log is asset lifecycle management. It stores all historical data in one place, making it easier to identify patterns, schedule predictive maintenance, and avoid costly repairs later on.

You should also know that predictive maintenance decreases maintenance costs by 5-10% and increases machine uptime by 10-20%. So you should definitely use this in your maintenance.

Types of Equipment Maintenance Log

There are many different types of equipment maintenance logs, divided according to their purposes. Let’s discuss each one.

- Manual Logs: These are the traditional paper-based maintenance log sheets completed after each service.

- Digital Logs: This type is software-based maintenance tracking systems that automate data entry and record equipment details.

- Preventive Maintenance Logs: It focuses on scheduled maintenance tasks to prevent breakdowns.

- Corrective Maintenance Logs: This next type documents repairs and services conducted after equipment malfunctions.

- Predictive Maintenance Logs: Lastly, predictive maintenance uses data analytics to predict when maintenance is required before a failure occurs.

Results of adopting predictive maintenance.

What’s Included in an Equipment Maintenance Log?

Typically, the following details are added to maintenance reports:

- Equipment Identification: The manufacturer's name, model, and serial number.

- Maintenance Dates: Specific dates when the servicing of equipment was performed.

- Type of Maintenance: Routine inspections, emergency repairs, or scheduled services.

- Issues Found: Any problems or defects discovered.

- Actions Taken: Repairs, part replacements, or adjustments made.

- Responsible Technician: The name and contact details of the maintenance person.

- Parts Used: Any spare parts or materials used during maintenance.

- Next Service Date: Scheduled date for the next servicing of equipment.

Who is Responsible for Equipment Maintenance

There are a few people who are directly responsible for the entire equipment maintenance tracking. These include:

- Facility Managers: These people oversee the routine maintenance program and ensure that logs are up-to-date.

- Equipment Operators: They conduct daily inspections and record minor maintenance tasks.

- Maintenance Technicians: These are the workers who actually perform the servicing of equipment and update the log.

Equipment Maintenance Log Example

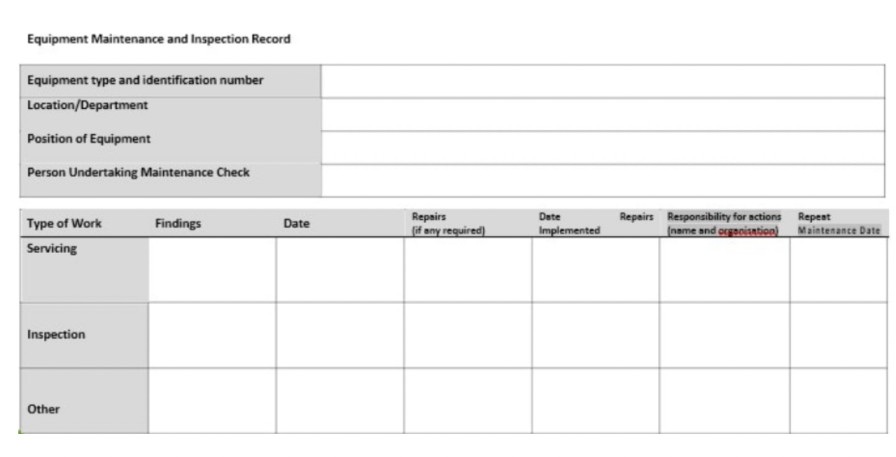

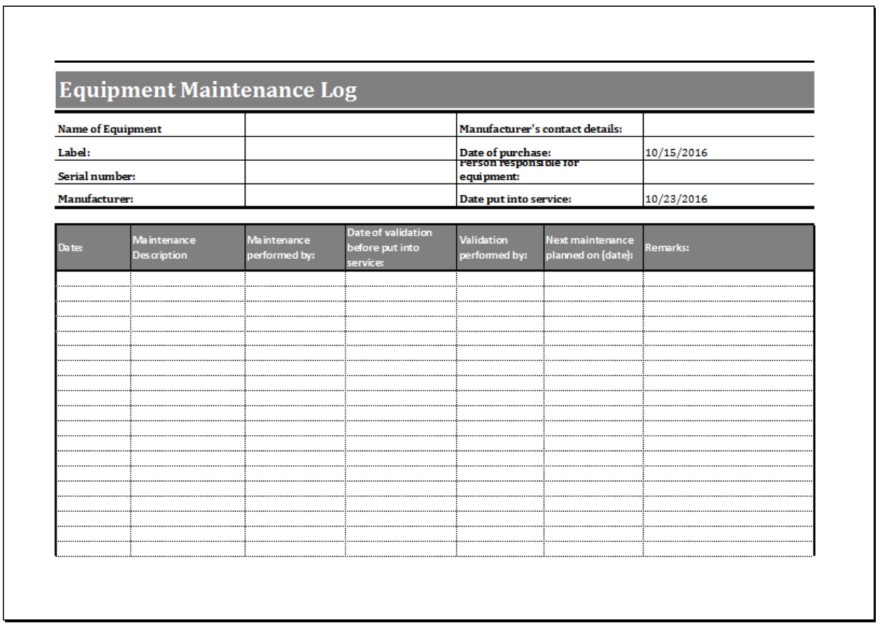

Here are a couple of maintenance logs for equipment templates that show exactly how a log sheet is usually designed for professional use. Check the images below.

Equipment Maintenance Log Example #1.

Equipment Maintenance Log Example #2.

As you can see above in example #1, there’s general information first and then some important details like the findings, repairs, date for both servicing and inspection.

After that in example #2, there’s again the general information including name of the equipment, label, serial number and the rest you can check above. Then there’s the maintenance log with description, when the maintenance was performed, validation date and who performed it and the next maintenance date.

Five Benefits of Equipment Maintenance Logs

Here are a few benefits of an equipment maintenance log that you should know about.

Minimizes Repair Costs

An up-to-date equipment maintenance log can help identify potential issues before they become bigger problems. This helps minimize the costs companies have to bear in case of emergency repairs.

Validates Warranty Claims

If you have a maintenance log, you can easily validate any warranty claims. For example, if any of your equipment breaks down within the warranty period, the manufacturer or service provider may require proof that the equipment has been properly maintained according to the terms of the warranty. Due to this, the manufacturers are inclined to honor the claim.

Improves Workplace Safety

An accurate equipment maintenance log shows the employers and managers that machines are being serviced regularly and that they are completely safe to operate. It also reduces the risk of accidents due to equipment failure, creating a safe environment for the workers.

Enhances Accountability

An equipment maintenance log clearly assigns responsibility for servicing each piece of equipment. Because of these logs, tasks are completed on time and, most importantly, according to the required standards. This accountability is critical in maintaining machinery's reliability.

Improves the Resale Value

When it's time to sell or upgrade equipment, a well-maintained maintenance sheet can significantly improve the resale value. Prospective buyers are more likely to invest in machinery that has a clear and documented history of maintenance.

Best Practices for Equipment Maintenance Log

The best practices that you should be following while maintaining maintenance logs include:

Consistency in Logging

If you want to build an efficient equipment maintenance tracking system, you need to be consistent. This means that you don’t fail to include a single entry. By doing so, you'll document all necessary details, making it easier to schedule future services and avoid missing any maintenance tasks.

Instead of relying on traditional log sheets, consider using a CMMS software like Itefy to make the process easier. These maintenance management tools offer a more efficient way to capture all the necessary details and saves much of your valuable time. It also reduces risk of errors and missed maintenance activities.

Detailed Record-Keeping

For this particular practice , you need to capture all the necessary details for the equipment maintenance log. It includes the service date, a description of any issues found, the actions taken to resolve those issues, and any parts used.

These details are essential for generating maintenance reports. These reports provide detailed insights into equipment performance, allowing you to make informed decisions about machine maintenance in the future.

Using CMMS Software for Maintenance Logs

Nowadays, CMMS software has made things easier, which means that these maintenance logs can now be kept online. These CMMS software offer several benefits, including easier data entry, automated scheduling, and the ability to generate reports quickly. They also reduce the risk of data loss, and because of this, your maintenance sheets are always up-to-date.

Itefy provides one of the most reliable equipment management software on both web browsers and mobile apps, making the whole process much easier. We also offer multiple tools to streamline your equipment maintenance logs.

Step-by-Step Guide to Creating an Equipment Maintenance Log

Now that you’re familiar with what an equipment maintenance log is, let’s take a look at how you can create one for your company.

Step #1: Identify the Equipment

The first step is to identify all the equipment that requires tracking. For this, you need to list every piece of machinery or equipment crucial to your operations. It should have all the essential details like the manufacturer's name, model, serial number, and any other unique identifiers that will help distinguish one piece of equipment from another.

Proper identification is extremely necessary to log in the correct maintenance details in the log sheets. This reduces the risk of confusion and missed services.

Step #2: Choose a Log Format

Next, decide the equipment maintenance log format you want to use. Several options are available, ranging from traditional paper-based logs to more sophisticated digital tools. Choosing the right format will eventually depend on your specific needs.

If you’re managing a small operation, a simple spreadsheet is more than enough. However, a digital log is recommended for larger operations, as it’s much more efficient and easy to use.

Step #3: Set Up the Log

Once you’ve chosen a format, you must create a template that includes all the necessary fields to capture relevant information for each maintenance activity. You can start by using the traditional paper method. By doing so keep a physical record of all maintenance activities, which can be easily referred to when needed.

However, instead of handling all this manually, you can simplify the process by using a tool. It will allow you to log all inventory, maintenance, and usage activities electronically. It also enables you to add additional information, track service history, and set reminders for future maintenance activities.

Step #4: Implement Consistent Record-Keeping

Consistency is key, as we discussed above. Every maintenance activity should be recorded immediately after it’s completed. Consistent record-keeping will ensure that your log remains up-to-date, which is essential for planning future maintenance.

To facilitate consistency, consider implementing an equipment maintenance template your team can use every time they perform maintenance. This template should be easy to fill out and include all the necessary fields.

Step #5: Review and Update Regularly

The final step in maintaining an effective equipment maintenance log is to review and update it regularly. Through periodic reviews, you can find any gaps in the maintenance history, spot recurring issues, and assess the overall condition of your equipment.

During the review process, check that all entries are complete and accurate. If any maintenance activities are missing or incomplete, follow up with the responsible technicians to ensure that the log is brought up to date.

Additionally, if you’re using a digital equipment maintenance tracking system, take advantage of the reporting features to generate maintenance reports. These software also send relevant notifications so you don’t get overwhelmed with information.

Common Challenges and Solutions in Equipment Maintenance Logging

It’s necessary to understand the problems companies face while maintaining logs and how they can get rid of them. Below are the challenges you could be facing and how you can resolve them.

Challenges in Maintaining Logs

So what do you think could be the challenges in maintaining log sheets? Let’s find out.

Incomplete Entries

One of the most frequent issues in maintaining equipment maintenance logs is incomplete entries. This can happen when maintenance staff forget to log activities immediately after servicing or when crucial details are missed due to time constraints or oversight.

Missed Service Updates

In a busy operational environment, scheduled maintenance activities can easily slip through the cracks. Without a reliable system in place to remind and prompt staff, service updates can be missed, leading to equipment running beyond its optimal maintenance schedule.

Loss of Paper Logs

Traditional paper-based logs are highly susceptible to loss, damage, or misplacement. Physical logs can be easily destroyed by environmental factors such as water, fire, or simple wear and tear over time. Additionally, the manual nature of paper logs makes them difficult to organize and retrieve when needed.

Businesses affected by unplanned downtime.

Solutions Using Digital Tools

To get rid of the problems mentioned above, you can switch to digital tools like the ones offered by Itefy. A few benefits of using tools for maintenance logs include:

Automated Logging

These tools eliminate incomplete entries and standardize the logs for consistency. It provides accurate and real-time recording of all maintenance activities. This way you can quickly access any files for a particular model or date.

Scheduled Maintenance Alerts

These digital tools automatically send reminders for upcoming maintenance. This reduces the risk of missed service updates and your machinery remains in top-notch condition.

Digital Storage and Accessibility

These tools also replace paper logs with secure, cloud-based digital logs that are easily searchable and retrievable. This protects your data from loss or damage.

Enhanced Data Accuracy

Lasly, they also minimize human errors with automated data entry and provide powerful reporting tools for generating accurate maintenance reports. You can further use these reports for insightful decisions.

Manage Your Equipment Maintenance Logs with Itefy

Equipment maintenance can be quite a headache if done manually. Managers are usually buried in paperwork, which can overwhelm them. Needless to say, the manual approach is time-consuming and also prone to errors.

That's why we recommend using Itefy’s Manufacturing Equipment Management Software. It will help you automate your logging tasks and ensure that they’re up-to-date and accurate. This tool also provides detailed insights so you can make better decisions and improve the efficiency and performance of your machinery.

Try Itefy now for 14 days without a charge!

Frequently Asked Questions

-

A maintenance chart can be created by listing all equipment in one place. After that, you set up a schedule for routine maintenance and track each task until its completion. Digital tools like Itefy can simplify this process by automating the scheduling and tracking of maintenance activities.

-

Equipment maintenance includes routine inspections, repairs, part replacements, and adjustments. It also includes other necessary activities for keeping machinery in optimal working condition. This involves both regular inspections and corrective repairs of your company’s assets.

-

To create a maintenance log, first identify the equipment and choose a log format between paperwork and digital tools like Itefy. Then, set up the log with all necessary fields such as manufacturer’s name, model, service dates, issues found, parts used and the next service date. Lastly, implement consistent record-keeping practices.

-

An equipment maintenance log is a record-keeping tool used to track the servicing, repairs, and upkeep of machinery and equipment. It ensures that all maintenance activities are properly documented, scheduled, and completed on time.