Trucking Logistics: What It Is, How It Works and The Business Model

Trucking logistics can be rewarding with the right strategies and business models. Learn what it is, how it works, and the best business models in our detailed guide.

In this article:

- What is Transport and Logistics and How Are They Different?

- Trucking Logistics Company - A Brief Overview

- Types of Trucking Logistics Companies

- 1. 3PLs

- 2. Freight Brokers

- A Detailed Analysis of Business Models for a Trucking Logistics Company

- 1. The Freight Broker Model

- 2. Digital Model

- 3. Hybrid Model

- 4. Gainsharing

- 5. Commission Model

- Conclusion

Trucking has been around for decades, but with the evolution of the industry and sustainability standards, it has seen a significant shift in recent years. According to the American Trucking Association, 72.6% of the country's freight by weight is moved by trucks. All businesses require efficient logistics, and trucks are at the heart of it.

Trucking logistics can be an expensive endeavor, with several costs adding up to create a hefty bill, such as fuel expenditures, maintenance costs, driver wages, and more. A trucking logistics company must adopt efficient business models that help it deliver products swiftly while maintaining healthy profit margins. So, what does logistics mean in trucking?

What are trucking logistics companies, how do they work, and which business models should they adopt? We’ll address these and related questions in this guide.

What is Transport and Logistics and How Are They Different?

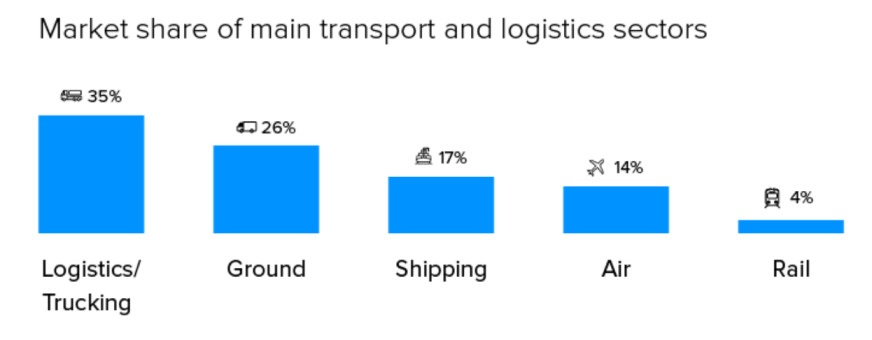

The transportation sector focuses only on moving goods from one place to another via roads, air, or ocean. On the other hand, logistics is a much broader concept that deals with managing product movement within a supply chain. It deals with order management, transportation management, inspection, customs clearance, warehousing, and more. Currently, trucking leads the pack regarding logistics, followed by ground and shipping logistics.

Trucking has the largest share in the logistics sector.

Trucking Logistics Company - A Brief Overview

A trucking logistics company is an organization that manages supply chains for different businesses. This includes scheduling, shipment tracking, carrier coordination, and acquiring the necessary permits and paperwork.

One of the primary reasons behind the existence of trucking logistics companies is that they make freight transportation much smoother. From the production facilities to their final destination, logistics companies ensure that the goods are transferred safely, quickly, and with real-time tracking.

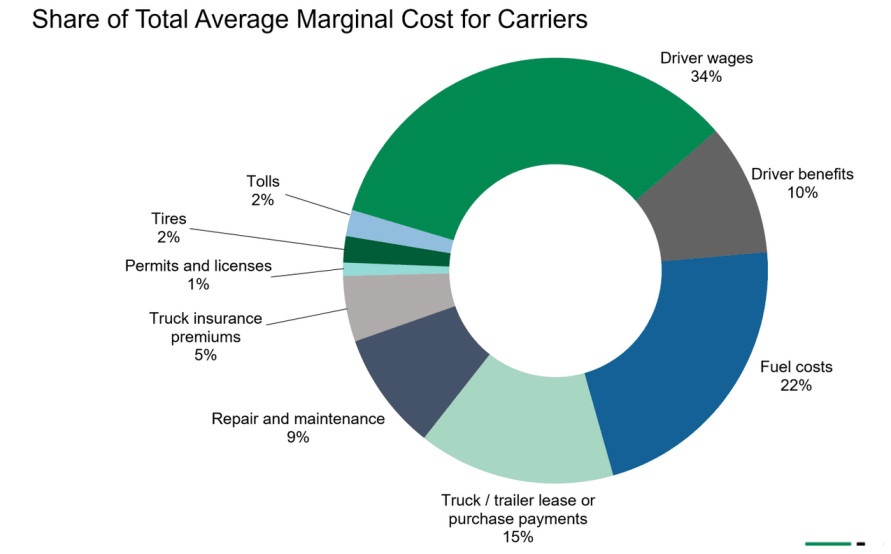

The five biggest costs of a trucking logistics company include:

- Driver wages and benefits

- Fuel

- Truck purchase or lease payments

- Maintenance & repair

- Insurance premiums

Trucking logistics companies deal with nine primary costs.

Types of Trucking Logistics Companies

Several trucking logistics companies are on the market today, mainly divided into third-party logistics providers (3PLs) and freight brokers.

1. 3PLs

A third-party logistics (3PL) company handles several supply chain elements for a business, such as shipping, storing, packing, access to technology, and much more. They can be divided into two categories: non-asset-based with no physical equipment.

On the other hand, asset-based carriers own trucks and hire drivers to operate them. They can include everyone from national-scale companies to companies with just one or two operational trucks.

2. Freight Brokers

Freight brokers have no assets of their own. They act as intermediaries between the business with goods and the logistics company that transports them. Freight brokers usually deal in single shipments and often collaborate with smaller shipping companies.

A Detailed Analysis of Business Models for a Trucking Logistics Company

A business model is a blueprint for your current or upcoming business that shows how it'll operate and earn its revenues, your pricing strategies, and how you'll reach your targets. It also involves a detailed study of the competitors, the factors differentiating you from them, marketing strategies, and more.

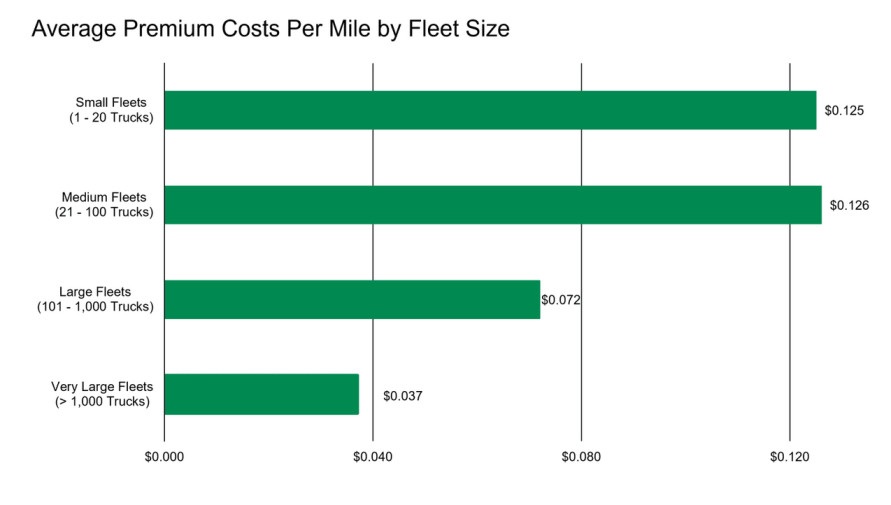

High costs make efficient business models a necessity.

While we have discussed the basics of the two predominant types of logistics companies, it is time to analyze them deeply. It'll help you understand which logistics transportation management model suits your market environment and goals.

1. The Freight Broker Model

As the name suggests, the freight brokerage model means a company serving as the “middle man,” a third-party service provider. Freight brokers link shipping and supply chain trucking companies, becoming indispensable parts of the process, as many shippers have various services.

Let's elaborate on it with an example. A freight brokerage company dealing in silicon chips will specialize in their shipment by occupying a niche within the market. Since silicon chips are delicate, they require special attention and must be transported in a certain range of humidity and temperature. Once your company understands these requirements, it will gain market share in the chip logistics sector.

Freight brokerages are divided into the Cradle to Grave (C2G) and the Chicago (buy/sell) Models. Let's address them both in detail here.

A. Cradle to the Grave (C2G) Model

The C2G is the most popular model in which freight brokerage works on everything from booking trucks to ensuring timely and safe deliveries. In this model, the broker is the only point of contact for the shipping company and handles all the essential aspects, such as:

- Covering loads

- Track and trace check calls

- Handling exceptions

- Roping in new customers

- Providing customer service

Usually, this model is adopted by independent companies with a distinct process to serve shippers.

Here are some of the pros and cons of this logistics transportation model.

Pros

- With a single point of contact for the shipper, the shipping process is simplified, and tracking becomes much easier. The broker controls everything and has complete ownership of the shipper/account.

- Since only one party handles everything, it can effectively handle customer queries. Similarly, the shipper has a single point of contact, which builds trust and ensures that the shipper receives consistent service.

- The broker has more control over the logistical process, ensuring that goods are delivered safely and timely.

Cons

- Each broker has a distinct customer service process, so there is a lack of process management on the brokerage side, which could lead to instability.

- Hard to train new hires on the C2G model, as it involves a wide variety of responsibilities and processes. It also doesn't help that these processes might vary from customer to customer.

- Prospecting for new clients is difficult since the brokerage is focused on fulfilling current commitments. If the broker concentrates too much on targeting new clients, their existing sales might be impacted.

B. Chicago (Buy/Sell) Model

It's called the Chicago Model because it was first popularized among Chicago-based brokers. In this Model, the freight brokerage business has two parts or two teams.

The first team consists of account managers who negotiate rates with clients. They handle various customer service aspects, such as getting quotes from multiple carriers, verifying delivery receipts and other documents, ensuring proper payment between both parties and filing timely claims.

The second team handles trucking and transportation. It deals with all aspects of trucking logistics, such as acquiring freight, monitoring fuel usage, gauging driver performance, and everything else. Companies adopting the Chicago Model usually use specialized software to monitor freight and drivers in real-time.

Let's discuss some pros and cons of this transportation and logistics model:

Pros

- Since the sales team is separate from the transportation team, there is no conflict of interest, and it becomes much easier to manage accounts.

- Results in rapid growth of each department and the overall business.

- Fewer responsibilities than in the C2G model make it easier to train new hires, as they can be assigned to the sales or transportation teams.

- With a more process-based approach, the brokerage has more control over the trucking operations, allowing it to monitor various KPIs and improve.

Cons

- Setting up two teams requires extra resources and adds complexity.

- Since smaller freight companies usually start with the C2G model, it is hard to transition to the Chicago Model later.

2. Digital Model

The digital model is a new entrant in the freight brokerage world but has quickly gained prominence due to its efficiency and convenience. This model has an online presence where customers can get quotes and book shipments. A broker usually does not require anything else to operate when using this business model. They only need a laptop or a phone connected to the internet, and they can handle everything.

Pros

- This model's digital footprint makes operating with fewer staff members easier.

- Brings efficiency to the business processes.

Cons

- Some customers might be less comfortable working with brokers using this model.

3. Hybrid Model

Some brokers use a combination of C2G, Chicago, and Digital models, with a dedicated sales team working in deep collaboration with the transportation teams. These companies rely heavily on technology to streamline operations and provide efficient services.

Pros

- An ideal model for companies looking for rapid growth with robust internal management.

- Combines the benefits of each model while minimizing their disadvantages.

Cons

- It also manages sales and logistics teams separately, which can be challenging.

4. Gainsharing

As the name suggests, the gainsharing model saves 3PLs and their customers significantly. For instance, a 3PL can say, “You're currently spending $200 per unit shipment costs, which we can bring down to $180, with a $10 fee.” This earns the 3PL $10 and saves the customer an equal amount. This relationship encourages the supplier and the trucking logistics company to constantly energize and enhance their business relationship.

Let's elaborate on this model with an example: Let's say a company, ABC, has outsourced warehousing and transportation to another company called XYZ at a fixed fee. They'll follow a new fee methodology if they adopt a gainsharing model instead. Both companies will agree on a baseline level of performance for metrics like inventory accuracy, delivery time, damage rates, and more.

Now, the trucking logistics company, which we named XYZ, performs better than the base level and reduces costs (let's say with route optimization); the savings will be shared by both companies according to a predefined formula. No wonder XYZ was incentivized to make its operations more efficient and earn more revenues. It also benefits ABC because it can get quality services at a lower price.

The Gainsharing Model has three popular forms: the Scanlon plan, the Rucker plan, and the Improshare plan.

A. The Scanlon Plan

The Scanlon plan's focus is quantity, determining how much work employees do and the difference between the standard and actual labor costs per unit.

This plan focuses on metrics like on-time delivery rates, fuel-efficient driving practices, and more in trucking logistics. Companies calculate the standard market cost for completing a trip and the cost at which their driver completes it. The difference is then given as a bonus to the driver.

B. The Rucker Plan

Unlike the Scanlon, the Rucker Plan focuses on quality. It highlights how efficiently someone's doing the work, which is why it involves metrics beyond just labor costs. For instance, it compares miles driven to the revenue generated, understanding how efficiently drivers have used their time. Similarly, it studies on-time deliveries, fuel cost savings, preventing breakdowns, and more.

The Rucker Plan divides total revenues by the combined labor, fuel, and overhead costs. If this ratio improves and the company earns additional revenues, they're shared as bonuses. It pushes everyone to ensure that the fleet is operating efficiently.

C. Improshare

Improshare promotes collaboration and teamwork, similar to the Scanlon plan. Where Scanlon focuses on labor costs, Improshare focuses on the time (number of hours) spent driving. Drivers who operate on optimized routes and minimize unnecessary stops can significantly decrease the number of driving hours.

Improshare calculates the standard number of hours for a specific route and the actual number of hours a driver takes to complete it. The trucking logistics company then distributes the difference as bonuses among drivers.

Let's discuss some pros and cons of the Gainsharing model.

Pros

- Drivers look for more efficient routes and practice fuel-saving techniques.

- The performance payout is usually self-funded, which helps a company save money.

- The efforts of drivers and other teams are aligned with the organizational goals.

Cons

- Sometimes, payouts are mandatory, even if the company's performance is down.

- Can cause a decline in some out-of-focus areas, such as safety.

5. Commission Model

In the Commission Model, the 3PLs are intermediaries between shippers and carriers. Companies using the commission model negotiate with carriers on the shippers’ behalf and fill empty capacity on trucks for carriers. The compensation they earn comes from the percentage of the total freight secured. Since the 3PL earns a percentage of the total freight, the commission structure is generally transparent, as it incentivizes the 3PL to find cost-effective solutions.

Some 3PLs use the shipper’s technology for booking and tracking. Still, most have dedicated software programs with advanced features like data analytics, real-time monitoring, and integration with the shipper's systems.

Although the shipper is the primary client in the commission model, 3PLs also work with carriers that can fill empty capacity, resulting in additional revenue for 3PLs. It creates a win-win situation for 3PLs through resource optimization.

Pros

- A transparent commission structure aligns 3PL’s goals with the shipper's and reduces costs.

- The 3PL looks for ways to minimize costs.

- Since the 3PL works with shippers and carriers, it can offer the shipper a broad selection of carriers and routes.

Cons

- The focus on lowering costs can result in compromised service quality.

- 3PLs might prefer carriers with high commission rates instead of those that offer better service quality.

Conclusion

Trucking logistics is a lucrative business that promises to deliver healthy profits in the long run. With a CAGR of 4.4%, companies can definitely turn this sector in their favor if they play it right. However, it's also crucial to remember that transport and logistics can be tricky, as the costs can add up pretty quickly.

The best way to minimize costs and maximize productivity is by using high-quality tracking technology provided by Itefy. We have helped hundreds of companies monitor and manage their vehicles, drivers, equipment, and much more. Whether you have a small fleet with 10 vehicles or a large fleet with hundreds of them, Itefy’s advanced monitoring and management system is ready to serve your needs.

It has all the necessary features, such as vehicle reservations and checkouts, condition tracking and solving, equipment usage scheduling, maintenance management, and so much more. So, start your free 14-day trial today and pick a pricing that suits your budget and requirements.