Fleet Vehicle Maintenance Tips To Reduce Repair Costs

Fleet vehicle maintenance is the best way to prevent costly repairs. Learn some of the most valuable and practical maintenance ideas in our detailed write-up.

In this article:

- Tips for Fleet Vehicle Maintenance

- 1. Create a Proactive and Preventive Maintenance Program

- 2. Deploy Pre-Trip Inspections and DVIRs

- 3. Reduce Mileage With Optimized Routes

- 4. Modify Driver Behavior

- 5. Upgrade Outdated Parts

- 6. Get Rid of Aging Vehicles

- Fleet Vehicle Maintenance With Itefy

Any fleet manager knows how challenging it is to maintain their fleet both on and off the road. They are doing everything possible to keep their bottom lines intact from rising fuel and repair costs. According to the American Transport Research Institute, the average fleet costs rose by 23.1%, including fuel, amounting to over $2 per mile for the first time since 2008.

Your fleet is the heart of your business, but if you constantly have to repair your vehicles, you'll be far less profitable. The good news is that effective fleet vehicle maintenance can minimize your repair costs. That's why in this guide, we'll help you with fleet car maintenance, so read on.

Tips for Fleet Vehicle Maintenance

1. Create a Proactive and Preventive Maintenance Program

Proactive planning is the foremost thing any fleet manager should do to curtail repair costs. Preventing costly breakdowns and minimizing unplanned downtime is possible through forecasting maintenance needs and strategically scheduling them.

Maintenance is usually cheaper than repairs.

By planning proactively, managers can timely acquire the required parts, allocate the workforce efficiently, and optimize the fleet vehicle maintenance process. Preventive measures enable managers to identify and resolve potential issues before they get out of hand.

A quality advanced software program can help schedule fleet vehicle maintenance to reduce the need for urgent repairs. These programs track engine use, fluid levels, and mileage data to remind you about preventive maintenance whenever it is due.

2. Deploy Pre-Trip Inspections and DVIRs

Pre-trip vehicle inspections go a long way toward ensuring vehicle and driver safety. However, it is essential to ensure that these fleet vehicle maintenance inspections are comprehensive, as a poorly performed one could lead to accidents, injuries, and higher repair costs.

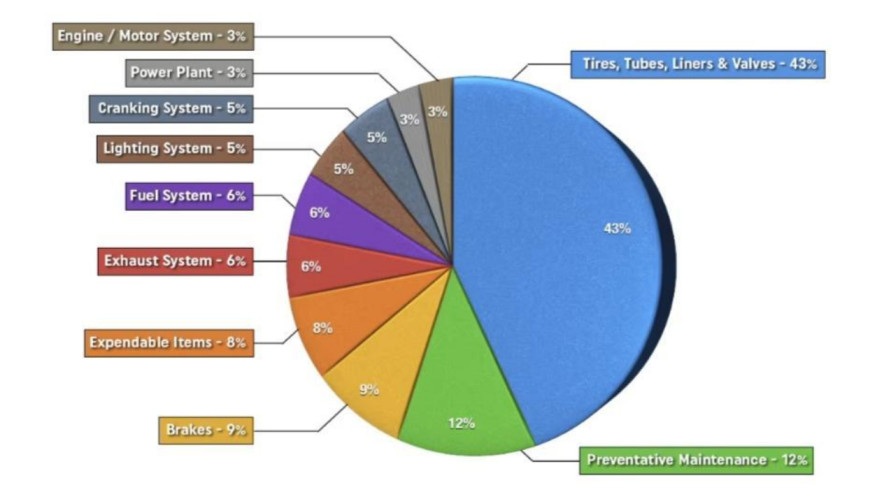

The top 10 maintenance and repair costs for trucks.

All drivers should be provided with detailed guides with relevant imagery and a list of risks they could face if they don't complete inspections. Open communication is the key here. For instance, drivers should contact the manager if they find an issue that needs fixing, and the latter should encourage the former to do so.

Driver Vehicle Inspection Report (DVIR)

DVIR is something no driver should compromise on. Usually, a pre-trip or DVIR inspection involves checking the following:

- Air pressure

- Fire extinguishers and other emergency equipment

- Air brakes

- Fuel tank

- Shock absorbers

- Driveshaft

- Fluid levels

- Air compressor

Any DVIR can be divided into two parts: the start and end of the day.

At the start of a new workday, drivers must review the last DVIR, check for defects, and sign them off. It is also crucial for them to confirm that everything else is in a good condition. This pre-trip inspection is described in detail in Federal Law 49 CFR 396.13.

Similarly, the driver should complete a DVIR at the end of the day—and if they operate more than one vehicle, they should create a separate DVIR for each. Any defects should be immediately reported to the fleet manager. Federal Law 49 CFR 396.11 details this process.

3. Reduce Mileage With Optimized Routes

The combination of GPS tracking and capable software can significantly reduce your trucks' mileage, prolonging its life. GPS trackers connected to external sensors and internal vehicle diagnostics also alert you about issues with your vehicles before it's too late. For instance, if the engine of one of your fleet vehicles drops its oil pressure or overheats, GPS trackers will instantly notify you about it.

They also help you optimize routes by providing real-time updates. As a fleet manager, you can change a driver's route in real time if you think they're on the wrong track. Similarly, it informs you if your vehicles are being used for unauthorized purposes, such as private use during work hours.

4. Modify Driver Behavior

Monitoring and correcting driver behavior is essential in a fleet maintenance plan to make sure your vehicles stay more on the road, not in a repair shop. Comprehensive driver management software will inform you about erratic driver behavior, such as hard stops, overspeeding, frequent restarts, and incorrect gear shifting.

You can incentivize drivers to change their behavior by offering additional money in their paychecks. Attach bonuses to a behavior score from 1 to 10 for various metrics and give them a final score. There should also be an option for the drivers to offset their poor performance in one aspect by performing better in others.

5. Upgrade Outdated Parts

Sometimes, it's better to upgrade outdated parts than repairing them repeatedly, which might cost you more. Replacing old parts gives your vehicles a new life and helps you make the most of it on the road. Here, the parts inventory management methods can be handy, ensuring you have every little detail at hand whenever needed. It helps you create a streamlined inventory, where the parts you use most are always available, and the obsolete ones take zero space.

6. Get Rid of Aging Vehicles

It's not always a good idea to keep driving your trustworthy vehicles. Sometimes, you should just get rid of them, as they might cost you more than obtaining new, better ones. If your vehicles require frequent repairs and disturb your fleet budget to an unmanageable extent, you know it's time to get new ones.

Fleet management software can be really helpful in this regard. It keeps you updated with each vehicle's mileage and usage, maintenance schedules, repair expenditures, and more. It informs you when a vehicle is no longer as useful as before and is becoming a liability with excessive repair costs.

Fleet Vehicle Maintenance With Itefy

Given the ever-increasing expenses of managing a fleet, it makes perfect sense for managers to cut costs wherever possible. Since effective fleet and vehicle maintenance can minimize repair costs, it should be their top priority. The tips described in this write-up will help you ensure your fleet performs to its full potential while reducing repair expenditures.

Thankfully, fleet vehicle maintenance can become convenient with Itefy's Transportation Fleet Management Software. Our class-leading system maintains a detailed cloud equipment database with condition tracking and maintenance management. It helps manage your fleet and prevents unwanted breakdowns, making for significant savings.

So, try our system today to stay on top of the fleet management game.