Constructions Equipment Maintenance: Maintain and Schedule Construction Equipment

Construction equipment maintenance is key to competing projects in specified time-frames. Let's learn what it is and how you can schedule it successfully.

In this article:

- Why Is Construction Equipment Maintenance Important?

- 1. Longevity

- 2. Safety

- 3. Efficiency and Productivity

- 4. A Culture of Ownership

- Construction Equipment Maintenance Checklist

- 1. Daily Maintenance Checks

- 2. Monthly Maintenance Checks

- 3. Annual Maintenance Checks

- 4. Construction Equipment Maintenance Cost

- Conclusion

Spending a dollar today on maintenance of construction equipment can save you ten. How and when you do maintenance decides how long your equipment lasts and how efficiently it performs during its lifetime. On the contrary, not maintaining it can lead to several issues, such as hefty repair costs and downtime.

So, what is construction equipment maintenance, and why is it important? How much can you expect to spend on it? What are the best strategies to maintain your construction equipment?

Let's address asset management in construction in detail below and clear up your confusion.

Why Is Construction Equipment Maintenance Important?

The construction industry in the US is 4.4% of the GDP, meaning thousands of companies use all kinds of equipment.

Any firm dealing with construction equipment should prioritize maintenance for several benefits, such as enhancing longevity, ensuring safety, and maximizing efficiency.

1. Longevity

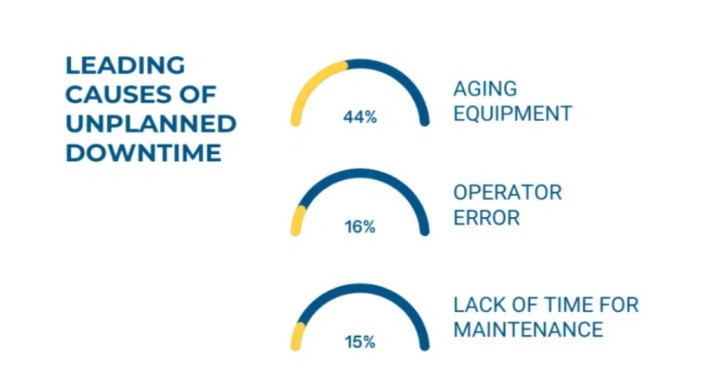

Construction firms invest significantly in their equipment, so wanting it to last a long time is reasonable. Regular construction equipment maintenance ensures that construction equipment has a long lifespan while performing efficiently. The process requires identifying minor issues before they become bigger problems, preventing costly repairs and unwanted downtime.

2. Safety

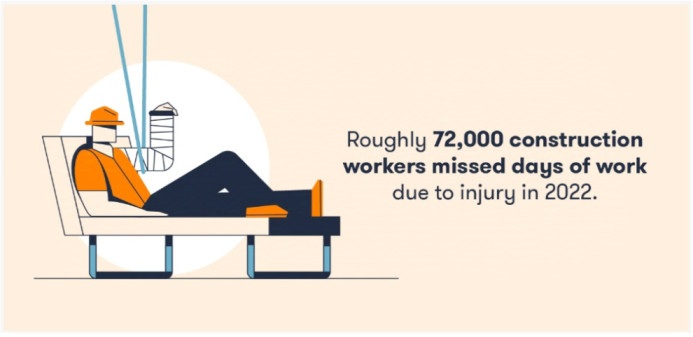

Safety is always a hotly debated topic, especially in the construction industry. That's because the nature of work and machinery in this industry comes with inherent risks. Ignoring construction equipment maintenance can also lead to severe legal and financial consequences.

The U.S. Department of Labor’s Occupational Safety and Health Administration (OSHA) recently fined a construction firm $199,761 for repeatedly violating safety regulations.

This shows how crucial safety is when managing construction projects. Regular inspections ensure you are always aware of faulty equipment, electric short-circuits, worn-out components, and much more. Instead of allowing these problems to become serious hazards, you can control them with construction equipment maintenance.

3. Efficiency and Productivity

Investing huge sums in construction equipment entails wanting excellent performance. If your expensive equipment performs average, the investment has gone to waste. Construction asset management ensures quality equipment doesn't throttle and performs at its capacity.

Timely construction equipment maintenance means avoiding breakdowns and downtimes, resulting in timely project completion. When your firm completes projects on time, it gains clients' trust and expands its business.

4. A Culture of Ownership

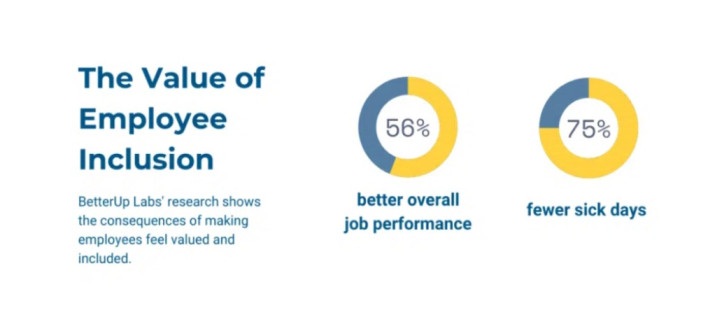

Construction equipment maintenance isn't just about tightening bolts and lubricating hinges. It also develops a sense of ownership and responsibility among workers and managers.

When workers treat equipment carefully and participate in regular maintenance of heavy equipment, they become an integral part of the process and take pride in operating it. This incentivizes workers to take care of equipment in the long run and reduces the likelihood of accidents.

Construction Equipment Maintenance Checklist

Construction projects involve a lot of machinery, and managing its maintenance is complex. The construction equipment maintenance industry will hit $33.96 billion by 2033, indicating increased complexity and demand for maintenance.

To make the process more efficient, it is ideal to divide maintenance into daily, monthly, and annual checks. Many companies now use asset management software to handle their maintenance checklists.

Here’s how a quality maintenance routine works:

1. Daily Maintenance Checks

The daily vehicle checks for excavators and other vehicles involve the following:

a). Fluid Levels

Proper fluid levels in excavators and other vehicles ensure smooth operation and prevent overheating. These fluids include coolants, oils, and hydraulic fluids.

b). Tires

Well-maintained tires can significantly improve a vehicle's operations. If the tires are properly inflated, they provide stability and traction to the vehicle while reducing load and improving oil efficiency. Regular tire inspection also ensures that any punctures and defects are detected before the vehicle is on the move to avoid accidents and further damage.

c). Lights and Signals

Construction firms are used to working night shifts in low-light conditions, so keeping lights and signals in top shape is crucial. Fully functional lights let workers see how and where a vehicle moves to prevent collisions with other equipment and workers.

2. Monthly Maintenance Checks

These physical asset management checks are more complex than daily checks and require more time.

a). Hydraulic Hoses and Connections

Hydraulic systems are prone to damage in the long run, so taking care of them is mandatory in the construction industry. Poorly maintained systems can lead to a loss of power and efficiency. When maintaining hydraulic systems, monitor any cracks, leaks, and signs of extra wear.

b). Engine Performance

Keeping the engine functioning efficiently is essential to lowering emissions and fuel consumption. Construction managers usually look for exhaust emissions, noises, abnormal vibrations, and the like while monitoring and maintaining engines. Addressing these issues timely can keep the engine running efficiently for a long period.

3. Annual Maintenance Checks

Annual maintenance checks take the longest to complete and are usually the most complex part of the construction equipment maintenance checklist, so they're required once or twice a year only.

a). Fluid Replacement

Fluid replacement is essential to keeping the equipment in great shape for years. That's especially true for the coolant and hydraulic fluid, which can get contaminated and damage critical components. Managers should drain and replace the older fluids per the manufacturer's guidelines during the annual check.

b). Braking System

Checking and fixing the braking system is also integral to annual checks. Monitor all the braking components, such as discs, braking pads, and related parts, for wear and tear. If damaged, they must be replaced immediately to avoid accidents.

c). Belts and Chains

Since belts and chains transfer power to various components, they're prone to wear and tear. In the long run, that can reduce efficiency. If belts and chains are too worn out, it is time to replace them according to the manufacturer's guidelines.

4. Construction Equipment Maintenance Cost

The maintenance costs for construction equipment depend upon the firm's size, the type of machinery, the workload, and other factors. However, a general picture can still be drawn for most organizations. It is ideal for organizations to budget 2-5% of their total replacement asset value (RAV).

A 2-5% RAV allows managers to estimate the construction equipment maintenance cost accurately, but it is not a hard and fast rule. Some organizations might be required to spend more because of the nature of their work or equipment.

Conclusion

Now that you know what construction equipment maintenance entails, you can make a comprehensive plan to tackle it and make your organization more productive.

However, doing it manually is almost impossible, considering the complexity of the projects and the machinery required to complete them. You need software like Itefy’s Asset Management System to guide your maintenance process.

It not only lets you schedule maintenance but also provides crucial insights that you can use to improve your strategies. Thanks to its timely updates, you can extend the lifespan of your equipment with timely maintenance.

So, start a free trial for our Asset Management System today and upgrade to a desired bundle when it ends.

Frequently Asked Questions

-

The equipment maintenance procedure is usually divided into daily, monthly, and yearly routines. The daily routines are the simplest, while the monthly and yearly routines are more complex and require more time to complete.

-

Construction equipment maintenance means keeping machinery and its components in excellent condition for maximum efficiency and longevity. Companies usually use asset management software to manage this process.