Inventory Tagging Systems: Everything You Need to Know

An inventory tagging system is more essential than ever to track and manage your inventory. Read this guide to understand its types, functions, and working principles.

In this article:

- What are Inventory Tags?

- Types of Inventory Tagging System

- 1. Barcode Inventory Tags

- 2. Quick Response (QR) Code Inventory Tags

- 3. RFID Inventory Tags

- 4. NFC Inventory Tags

- 5. Sequential Number Inventory Tags

- 6. Color-Coded Inventory Tags

- Benefits and Importance of Using Tags for Inventory

- 1. A Unique Identity for Each Asset

- 2. Efficient Tracking

- 3. Remove Manual Workloads

- 4. Minimize Theft and Loss

- 5. Save Costs

- Inventory Tagging System - Best Practices

- 1. Pick the Right Asset Tagging System

- 2. Tag High-value Assets

- 3. Include All Data

- 4. Use Alongside an Asset Management Software

- Conclusion

No matter which industry you're in, effective inventory management is the bedrock of operational success. Accurate data is critical to making the best decisions for your company, and that can only happen by knowing where your inventory is and how it's being used. Given the complexity of inventory these days, counting everything manually is no longer viable.

That's where inventory tagging comes in. It makes it easier for businesses to track how much of something they have in stock, when it was last updated, and how long it will last. According to estimates, tagging can improve inventory accuracy by up to 99%.

So, what is an inventory tagging system, actually? How does it label inventory management? What are its types, and how do they differ from each other? Let's answer all of these questions below.

What are Inventory Tags?

Inventory tags are specialized physical markers or labels to identify and track inventory. These physical inventory tags track your assets through various stages so you know when, where, and how they are used.

Since they primarily act as identifiers, inventory tags, such as barcodes, RFID chips, or QR codes, have unique codes that your digital asset management system can interpret and store.

However, the inventory labeling system goes way beyond identification these days. Have you ever scanned a barcode through your smartphone? If you do and follow the link provided, it'll take you to a browser page with all the relevant product information, such as production date, expiry date, batch number, color, and much more. So, inventory tags act as stores of product information that you can scan and instantly access all the critical product information.

Inventory tags offer a precise way of tracking inventory, bridging the physical world and the associated digital systems. As a result, they ensure that all of your physical inventory data is stored in your digital management system.

Types of Inventory Tagging System

Today, inventory tags come in various types, so every business can choose one according to its use case and environment. Before choosing inventory tags, it's crucial to understand them in detail.

1. Barcode Inventory Tags

Barcodes are the most widely used inventory tags today. You'll witness them on almost every product, consisting of vertical lines of varying thickness representing different numbers. The data is modified by changing the lines' length, width, and spacing. When you scan the barcode with a scanner, it translates those lines into readable data that is displayed on a screen.

Barcodes come in two types: 1D and 2D. The most popular one-dimensional barcode is UPC, further divided into EAN and its types. On the other hand, the most popular 2D barcodes are QR Code, Data Matrix Code with its variants, Aztec Code, PDF 417, and more.

One of the major reasons behind their immense popularity is cost-effectiveness. Similarly, they are highly accurate and reduce errors usually associated with manual asset tracking. They are ideal for businesses looking to track inventory without spending a fortune. No wonder the barcode scanner market will reach $10.1 billion by 2030, indicating their increasing popularity and usage.

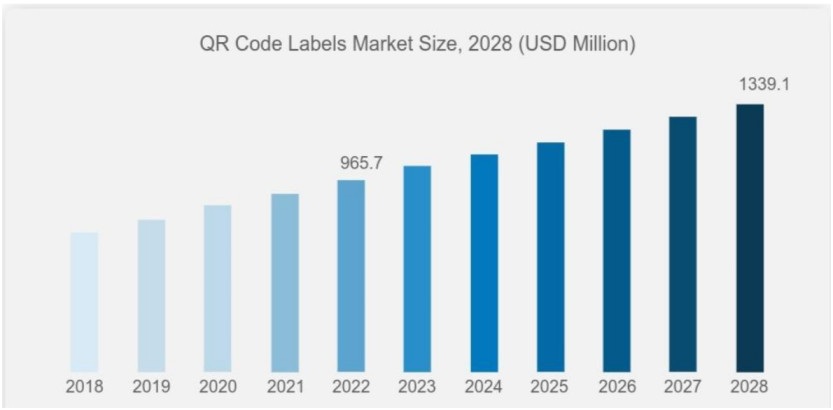

2. Quick Response (QR) Code Inventory Tags

QR codes are advanced two-dimensional versions of traditional barcodes, storing more data than the latter. They can be scanned using several devices, including smartphones, making them highly accessible for every business. Companies that want to save money don't have to buy dedicated scanners to scan QR codes. Today, there are five QR Code standards: AIM International, JEIDA, JIS, ISO, and GS1.

Graph showing the QR Code Labels Market Size

Since QR codes can store more information in images, URLs, and longer texts, they are ideal for businesses that require image identification of their assets. QR codes also have error-correction capabilities, meaning they can store information even when they suffer up to 30% damage.

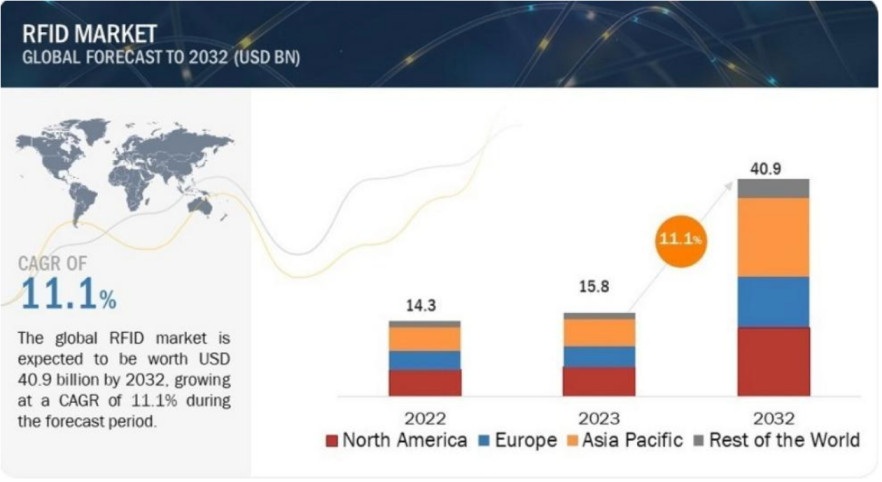

3. RFID Inventory Tags

Radio-frequency identification (RFID) tags detect and track assets using electromagnetic fields. They have high storage capabilities and can be scanned at large distances, even when they’re not in the line of sight. Since companies wanted contactless tracking solutions after the COVID-19 crisis, RFID tags became highly popular. Owing to their increasing appeal, the RFID market will be worth $40.9 billion by 2032.

RFID Market Size

There are three types of RFID tags available today:

- Passive

- Active

- Semi-passive

1. Passive RFID Tags

They do not have a power source. Instead, they draw power from the RFID scanner through radio waves and transfer the data. They come in low-frequency (LF) tags with a 10cm range, high-frequency (HF) tags with a 1-meter range, and ultra-high-frequency (UHF) tags with a range of up to 12 meters.

2. Active RFID Tags

Active RFID tags usually contain a battery, which means they have their own power source and don't need to draw any power from the scanner. Since they have a larger memory and extended range, they are helpful when businesses want to track their inventory over long distances, such as expensive assets like computers, vehicles, and more.

3. Semi-Passive RFID Tags

Semi-Passive RFID tags lie in the middle of active and passive RFID tags. Although they have their own battery, it doesn't help them broadcast a signal. Instead, it energizes the internal circuitry to increase the tag's sensitivity and range. Their range also lies between active and passive tags - larger than the former but smaller than the latter. They can usually transfer data up to 30 meters.

Since they are the perfect middle ground between active and passive variants, they can be used when companies want to track assets at a longer distance without paying for active tags.

4. NFC Inventory Tags

Near-field communication (NFC) uses RFID technology but offers something different. They are useful for tracking inventory when there are a few centimeters between the scanner and the tag. The major difference between RFID and NFC is that the latter offers two-way communication between electronic devices and tags.

These inventory control tags rely on cloud systems, meaning you can track your inventory wherever you are, and the data will be stored in your digital registry. Another advantage of NFC tracking is that it uses a Single-Page Application (SPA) that fits perfectly on a single smartphone or tablet screen. So, it doesn't require staff retraining.

5. Sequential Number Inventory Tags

If we look at manual tracking systems, sequential number tags are probably the most popular. Although they are not as popular as once, some companies still use them. It is a simple system that involves numbering the items you have in the inventory and later identifying them based on that numbering. No scanners, batteries, or even digital systems are involved in it.

6. Color-Coded Inventory Tags

As their name suggests, color-coded tags use colors to identify and track inventory. They can be used alone or combined with other tracking systems. Companies use these tags to categorize items based on their use cases or potential hazards. For instance, fire equipment, emergency buttons, and more are color-coded tags.

Benefits and Importance of Using Tags for Inventory

Tracking your assets is essential for operational continuity and peak productivity. Let's explore how an inventory labeling system can help you achieve that.

1. A Unique Identity for Each Asset

Your office will likely have computers from the same manufacturer, which you have probably bought under a contract. Similarly, the furniture you use is usually also from a single supplier. So, how can you distinguish these items when they look the same?

The answer is inventory tags. The assets look the same, but they have had a different history, use cases, owners, and so on. Instead of using sticky notes, you can use asset tags to scan and identify them much more accurately.

2. Efficient Tracking

Identifying assets for the sake of identification doesn't serve any purpose. It's all about translating that into efficient tracking so that you know where your assets are and who is using them. Inventory tags make asset tracking convenient, telling you the exact location, condition, and status within seconds. As a result, you have a detailed record of every asset you own.

3. Remove Manual Workloads

Asset tracking without asset tags is a tedious process that requires writing everything down manually. This means you'll need to search for each asset separately in the database and then record its relevant information. Manual data entry consumes much of your valuable time and energy and increases the probability of inaccuracies. So, isn't it much better to record data accurately using inventory tracking tags?

4. Minimize Theft and Loss

Inventory tags can prove instrumental in preventing theft and loss of valuable assets. When you can track your equipment on the go, you can quickly detect if an item has been stolen or an unauthorized person has access to it. In such a scenario, your asset management software instantly notifies you, allowing you to take immediate corrective actions. This kind of swift theft prevention is almost impossible with manual tracking.

5. Save Costs

Making inventory tracking more efficient with tags saves you a lot of money through asset optimization. You know exactly the number you want to order since you're always aware of your current stock levels. The asset management software updates you whenever an asset has reached the Reorder Point, prompting you to reorder a precise number. Similarly, knowing the exact number of items you have in stock prevents over-ordering.

Inventory Tagging System - Best Practices

There are numerous inventory tagging systems available today, but the best one for you is the one that suits your business environment. Some general principles or practices apply to every business that wants to use inventory tagging systems. Let's discuss them in detail below.

1. Pick the Right Asset Tagging System

Multiple tagging technologies are available today, from barcodes to RFID, offering some benefits. For instance, RFID tags can be scanned from large distances without a line of sight. Barcodes are quite inexpensive and can be used on several items without worrying about costs. QR code brings extra functionality, as it is an advanced version of the basic barcode.

There is no single asset tagging system that works well for all businesses. Select one that suits your business budget and requirements.

2. Tag High-value Assets

You spend the most on your high-value assets, such as computers, so tracking them through tagging should be a top priority. It brings peace of mind by ensuring you save them from being stolen or lost. It also ensures that those assets are being used in the right place for the intended purpose.

Regular tracking of high-value assets means you'll be instantly notified when they need maintenance or service. Instead of wasting time, you can maintain and keep them in optimal condition.

3. Include All Data

When tracking inventory using tags, make sure you're recording every detail about it. It prevents confusion and makes inventory tracking much more accurate. Here is how to label inventory items:

- ID number

- Description of the asset

- Asset's price

- Asset's location

- Acquisition date

- Expiry date (if applicable)

4. Use Alongside an Asset Management Software

Asset tags are an excellent way of keeping track of your valuable equipment. However, they alone aren't enough, and they need robust digital backing, which comes from comprehensive asset management software. It serves as the central nervous system for your inventory, recording and presenting all the information, such as acquisition prices, dates, locations, maintenance schedules, end-of-life periods, and the like. Moreover, it generates detailed reports on asset usage to help you make informed decisions.

Conclusion

Asset tagging systems can significantly improve the efficiency of your business operations. You can make flawless decisions when you select the tagging technology, record all the crucial data, and know how your assets are being used.

To create the perfect asset tracking system, you must use asset tagging with a capable Asset Management System like the one from Itefy. Our system isn't just a collection of random data points; it is a comprehensive data registry that contains everything about your equipment. It is flexible enough to do location tracking, issue management, maintenance logging, and much more.

It's about time you tracked your assets efficiently. Purchase our affordable Asset Management System and get all the valuable insights you need.