The Ultimate Truck Maintenance Checklist for 2024

Looking for a truck maintenance checklist to keep your fleet on the road for longer? Here’s a list broken down into daily, weekly, and monthly milestones.

In this article:

- What Are the Types of Vehicle Maintenance?

- Preventive Maintenance (PM)

- Reactive Maintenance

- Predictive Maintenance

- What is a Preventive Truck Maintenance Checklist?

- The Ultimate Truck Maintenance Checklist for 2024

- Daily Maintenance Tasks

- Tire Inspection

- Fluid Levels

- Lights and Signals

- Windshield and Mirrors

- Weekly Maintenance Tasks

- Battery Check

- Air Filter Inspection

- Brake System Inspection

- Hoses and Belts

- Monthly Maintenance Tasks

- Suspension and Steering Components

- HVAC System Check

- Engine Inspection

- Benefits of a Preventive Truck Maintenance Strategy

- Reduced Downtime and Emergency Repairs

- Cost Savings Over Time

- Extended Vehicle Lifespan

- Enhanced Safety for Drivers and Cargo

- Conclusion

No fleet manager likes unexpected breakdowns and expensive repairs, especially on a productive, sunny afternoon. Think about having a truck sidelined when you’re balancing deadlines, customer demands, and tight delivery windows. Feels like a bad dream, right?

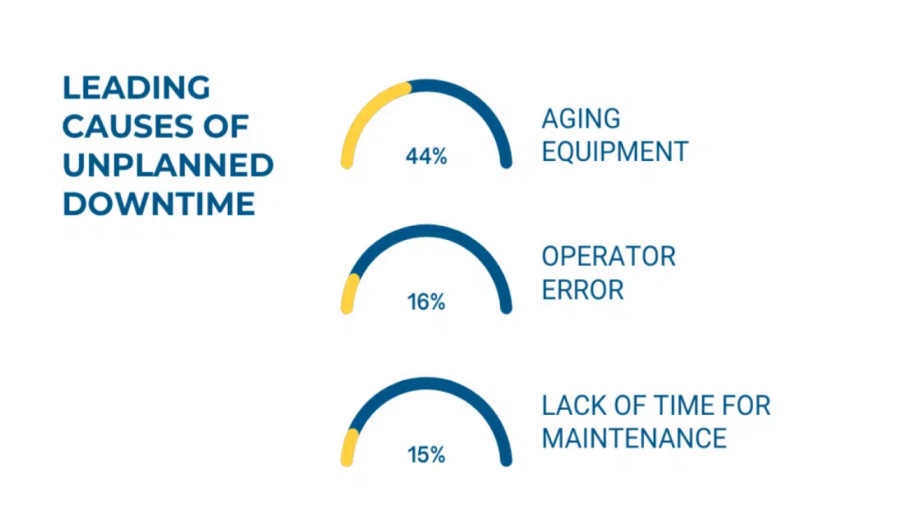

Unplanned downtime costs $22,000 per minute for the average automotive manufacturer, contributing to around $50 billion in lost production revenue. However, a sound truck maintenance routine can avoid many of these issues.

A well-planned maintenance truck schedule helps keep your trucks (and drivers) on the road and your operations running smoothly. Need help on where to start? Here’s a truck maintenance checklist to keep your fleet moving, from inspecting brake systems to maintaining engine performance.

What Are the Types of Vehicle Maintenance?

Following a truck maintenance checklist isn’t enough to keep your trucks on the road. You need to understand the dynamics of vehicle maintenance to draft a cohesive upkeep strategy for your fleet. This involves knowing what types of vehicle maintenance are needed and when to perform them to ensure the prime health of your trucks.

Preventive Maintenance (PM)

Preventive maintenance involves scheduled, routine maintenance check-ins to prevent future breakdowns and expensive repairs. This strategy is based on a proactive approach to fixing things before they break, addressing wear and tear on time.

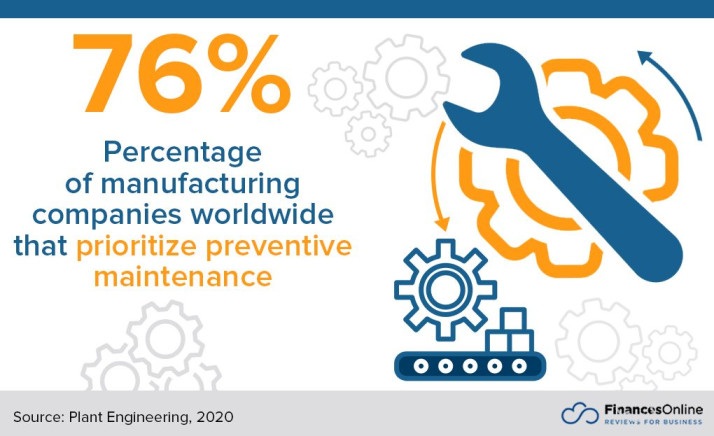

It extends the life of your trucks and prevents unplanned downtime (and mechanical failures). As per statistics, a preventive approach can help companies reduce their costs by 12% to 18% compared to reactive maintenance. Every dollar spent on PM today saves around $5 tomorrow.

A preventive truck maintenance checklist includes the following:

- Regular oil changes

- Tire rotations

- Filter replacements

- Brake inspections

- Fluid checks

Companies that prioritize preventive maintenance

Source: Financesonline

Reactive Maintenance

Reactive maintenance is a run-to-failure approach that involves fixing vehicles only after they break or malfunction. In other words, you wait for your trucks to experience a mechanical failure, like brake systems wearing out unexpectedly or a tire puncture on the road. Due to the unplanned nature of reactive maintenance, it is highly unsuitable in the commercial transport industry as it disrupts the productivity and efficiency of your operations.

Predictive Maintenance

Predictive maintenance involves using advanced sensors and data to predict when a failure might occur. Using this data-driven analysis, fleet managers implement fixes just in time to prevent breakdowns. Examples include using sensors to monitor oil quality by detecting contaminants or analyzing data on engine performance (based on the usage patterns of timing belts or spark plugs). So, instead of following a fixed maintenance calendar, predictive maintenance relies on the actual condition of your asset.

What is a Preventive Truck Maintenance Checklist?

A preventive truck maintenance checklist is a structured directory of inspections that ensures a truck stays in the best working condition. It lists routine maintenance tasks that need to be performed regularly based on time intervals or mileage to prevent mechanical failures.

This checklist guides truck owners and fleet managers to inspect, service, and maintain all parts of a truck in a systematic manner.

Usually, a truck maintenance checklist covers everything from engine and brakes to light, tires, and fluids. It also extends to the electrical system, exhaust, and suspension at times. Since the checklist is divided into daily, weekly, and monthly checkpoints, it is easier to upkeep your truck comprehensively.

Causes of unplanned downtime

Source: Gocodes

The Ultimate Truck Maintenance Checklist for 2024

Here’s the ultimate truck maintenance checklist broken down into daily, weekly, and monthly milestones to help you achieve your goals.

Daily Maintenance Tasks

Tire Inspection

Underinflated tires can increase fuel consumption and pose safety hazards for both the driver and your cargo. Therefore, inspect the tire pressure daily to ensure it is inflated to the manufacturer’s recommended level.

Before going on long trips, check the tread depth to rule out the risk of unexpected tire blowouts. Also, perform a visual maintenance check for cuts, punctures, and unusual wear patterns on your tires.

Fluid Levels

Check the engine oil levels regularly using a dipstick and top up the tank if necessary. Apart from that, look at the coolant levels in the reservoir but ensure the engine is cool before checking. Inspect the brake fluid level and match it to the manufacturer’s recommendations.

Lights and Signals

Test turn all indicators, like signals, hazard lights, and brake lights before departure and have someone else confirm they’re working. Also, check that the headlights, high beams, taillights are not faulty to avoid the risk of fines.

Windshield and Mirrors

As part of the pre-trip maintenance scheduling, ensure that the windshield wipers are functioning and don’t leave streaks. Likewise, top up the washer fluid reservoir.

Weekly Maintenance Tasks

Battery Check

You don’t want your drivers to encounter battery-related issues while on the road. Thus, inspect the battery terminals every week to spot signs of corrosion or loose connections. Additionally, test the battery voltage using a multimeter and replace it promptly if it shows low charge or significant wear.

Air Filter Inspection

A clean air filter is necessary for better engine performance and fuel efficiency. Most automobile manufacturers suggest replacing your air filters every 15,000 to 30,000 miles. Therefore, you should examine the condition of the air filter and clean it if it is clogged. If your trucks drive on high-pollution areas or dirt roads, narrow down the replacement mileage.

Brake System Inspection

Every week, inspect your trucks' brake pads and discs for wear and tear and replace them if they’re worn out. Furthermore, if your truck has an air brake, inspect the lines for leaks and check the air pressure, too.

Hoses and Belts

Worn belts can sometimes cause power steering failure or overheating. Hence, look at engine hoses and belts weekly for signs of cracks, fraying, or leaks. Also, ensure that the belts are properly tensioned and adjusted.

Monthly Maintenance Tasks

Suspension and Steering Components

Examine the suspension system for shocks and struts, while keeping an eye out for signs of wear of the suspension components. There should be no handling issues or unusual noises in the system. Subsequently, inspect the alignment and proper operation of the steering wheel for any looseness or play.

HVAC System Check

In your heavy truck maintenance checklist, include monthly visits by a qualified mechanic to service your HVAC system. The mechanic can check and verify the thermostat, radiator, hoses, and coolant level to ensure there are no leaks. After all, the cooling system plays an important role in keeping your truck from overheating, so it deserves special attention.

Engine Inspection

Once a month, a qualified mechanic should conduct a detailed inspection of the engine to detect any minor problems before they sideline your truck. An emission test should also be conducted.

Benefits of a Preventive Truck Maintenance Strategy

Following this high-standard commercial truck maintenance checklist is important if you want to avoid sudden breakdowns while you or your drivers are out delivering shipments. It involves servicing your vehicles at regular checkpoints to avoid the risk of lost productivity and costly replacements.

Here are the benefits of using a truck service checklist.

Reduced Downtime and Emergency Repairs

A mechanical failure on the road leads to lost revenue and missed deadlines — and also tarnishes your business reputation. With so much at stake, following a regular truck maintenance checklist becomes crucial as it addresses potential risks on time. This reduces the risk of your trucks being sidelined on a random day, thereby throwing off your entire schedule.

Cost Savings Over Time

We get it: routine maintenance requires a substantial upfront investment. However, it’s still a fraction of the cost compared to tow services, emergency fixes, and lost business due to downtime. If you think about it, replacing worn brake pads on schedule is far cheaper than replacing an entire brake system after it fails. An ounce of prevention is worth a pound of cure.

Extended Vehicle Lifespan

As any fleet owner knows, trucks are a major investment and maximizing their lifespan is a priority. This is where the use of a regular truck maintenance checklist comes in, preventing premature wear of your vehicles. Plus, a truck that is routinely cared for is less likely to need a costly yearly replacement, which gives you more value for your investment.

Enhanced Safety for Drivers and Cargo

According to the Federal Motor Carrier Safety Administration (FMCSA), vehicle-related issues like brake system failures contribute to around 29% of truck accidents. This necessitates the need for a preventive maintenance schedule, which reduces the chances of on-the-road breakdowns. It also helps keep your drivers safer and ensures your cargo arrives intact.

Conclusion

Trucking operations are heavily reliant on reliability and productivity, reflecting the need for a well-structured truck maintenance checklist. If you want to keep your fleet delivering cargo without delays, remember to allocate time for daily, monthly, and weekly inspections. This ensures that you stay on top of commercial vehicle servicing, which results in a more efficient bottom line.

To further streamline maintenance and have better control over your fleet, trust Itefy’s Asset and Equipment Management Software. With Itefy, you’ll never miss a maintenance check again, thanks to custom notifications that keep you informed.

So, if you want to ensure that your trucks keep moving in prime health, sign up for Itefy today.

Frequently Asked Questions

-

A detailed equipment maintenance log helps you stay on top of your maintenance checklist by recording the condition, servicing history, and repair records of your asset. You can also use maintenance management software like Itefy for regular notifications and reminders of asset maintenance, which helps you keep your trucks in prime health.

-

To maintain a pickup truck, change the oil and filter as recommended by your truck’s manufacturer. Plus, pay attention to the fluid levels and keep them topped up at all times. Get your battery services by a mechanic and always take note of unusual noises.

-

As part of your regular maintenance, check the tire pressure and fluid levels (engine oil, coolant, brake fluid) and ensure all lights and signals are working. Inspect the battery for any signs of corrosion and wear on the brake pads and discs. Also, review the fuel system and engine performance at regular intervals.