Warehouse Logistics: Benefits, Working Principles & Challenges

Warehouses are big businesses with significant logistical challenges. Learn what warehouse logistics is, how improving it benefits, and much more in this detailed write-up.

In this article:

- What are Warehouse Logistics?

- Benefits of Warehouse Logistics

- 1. Enhanced Efficiency

- 2. Cost Reduction

- 3. Better Customer Satisfaction

- 4. Strategic Decision-Making

- Working Principles for Warehouse Logistics

- 1. Accuracy

- 2. Operational Efficiency

- 3. Tracking and Reporting

- Core Challenges in Warehouse Logistics

- 1. Inventory Inaccuracies

- 2. Duplicate Processes

- 3. Poor Warehouse Layout

- Manage Your Warehouse With Itefy

Warehouses are a major chunk of any economy: several items we see around spend some time in warehouses before they are sent to customers or displayed on storefronts. A lot goes into warehouse logistics, from tracking inventory to ensuring an optimal layout. Thanks to e-commerce, the number of warehouses is increasing, expected to reach 180,000 by 2025.

That's exactly what we'll explore in this write-up. Read one and find out what logistics warehousing is, the benefits quality warehousing logistics offers, and the challenges you face along the way.

What are Warehouse Logistics?

We must first understand the logistics concept to grasp the idea of warehouse and logistics. Logistics deals with planning, managing, optimizing, and implementing complex operations. It is an integral part of all industries where management of physical and non-physical goods is required.

The number of warehouses and the need for quality logistics will increase.

Warehouse logistics deals with these complex factors in a warehouse, such as receiving and shipping physical goods. However, it is not just limited to physical goods, as abstract goods like time and information are also accounted for.

Its purpose is to keep your warehouse running smoothly, where operations don't face any unnecessary hindrances. Here are the things that a usual warehouse logistics policy covers:

- Pest control

- Damaged goods handling

- Safety Policies

- Customer returns handling

- Human resource management

Benefits of Warehouse Logistics

After its brief understanding, let's discuss the benefits of logistics warehouse management.

1. Enhanced Efficiency

Efficiency should be a top priority for any business, and streamlining warehouse operations helps you achieve that throughout the supply chain. A warehouse handles several operations, such as receiving inventory, storing it, fulfilling orders, and more - optimizing them can significantly reduce lead times and enhance output. It increases a business's productivity and profitability and helps it expand operations.

2. Cost Reduction

Besides operational efficiency, businesses also try to minimize costs to maximize profits. Making supply chain warehouse logistics efficient results in a direct reduction of costs. Eliminating labor overload, overstocking, and optimizing storage space can significantly help warehouses improve their bottom lines.

3. Better Customer Satisfaction

Customers are at the heart of any business, so their satisfaction should be paramount. When you fulfill orders on time and ensure that customers receive them on the given date, you're more likely to have a loyal customer base. According to a report, 85% of online customers won't buy from a retailer again after experiencing order delays. It also minimizes shipping errors and shows how much stock is left for a particular item.

4. Strategic Decision-Making

Informed decision-making is the key to increasing profits and ensuring a wide footprint for your business. Effective warehouse logistics provides quality and timely data to help you make informed decisions. Here are a few KPIs that a comprehensive logistics plan measures:

- Inventory turnover ratios

- Order fulfillment rates

- Warehouse utilization rates

Tracking these KPIs makes it easier to grab opportunities, identify areas for improvement, and minimize risks to unlock long-term success.

Working Principles for Warehouse Logistics

Several warehouse logistics principles help you run a warehouse smoothly and satisfy clients. Let’s discuss these principles and understand how they play out for a warehouse.

1. Accuracy

Accuracy is one of the most fundamental principles of quality warehousing logistics. After all, you must store thousands of products and ship them to clients at the right locations.

Training employees ensure that they perform their jobs accurately. When their training is paired with warehouse inventory management software, the results are impressive. The software helps you determine your inventory, how much is going out, and more.

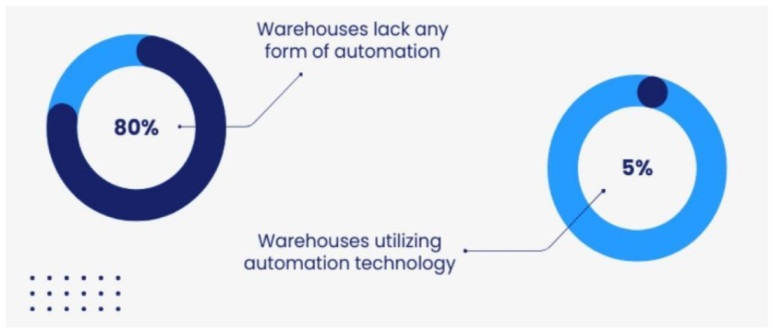

The majority of warehouses still lack automation.

Lower touch frequency is one of the most important factors in inventory handling. Touch frequency means the number of times a particular item is handled after entering the warehouse. Here are a few ways to keep touch frequency low:

- Large warehouses should have item retrieval spaces. Around 59% of warehouses report that they use 90% of their space, which is a big number.

- Make containers, bins, and shelves easily readable.

- Adjust the shelves if required to make it easier for staff to retrieve items.

2. Operational Efficiency

Everyday success in the warehouse business depends on operational efficiency. One-way warehouse logistics is the most popular and effective way of enhancing operational efficiency. It means all warehouse products, including returns, are processed in one direction only. One-way logistics minimizes bottlenecks, makes it easier for staff to move around, and ensures stocks and returns don't mix.

The best way to create one-way logistics in your warehouse is to hire a qualified warehouse manager and conduct an ABC analysis twice or thrice a year. The ABC analysis determines which products are the most profitable and separates them from the least profitable ones.

Products in the A category are most profitable; the B category contains occasionally purchased loss leaders, and the C category has products posing active losses and should be phased out of the digital catalog.

3. Tracking and Reporting

Each stage of warehouse operations must be tracked and reported. Detailed analysis and reports identify missing products, return issues, shipping delays, and other issues that might otherwise go unnoticed. Once you have identified problems in your warehouse operations through tracking and reporting, you can implement the right solutions to address them.

Core Challenges in Warehouse Logistics

Warehouse logistics faces various challenges that can impact operational efficiency. Addressing these challenges head-on is imperative to optimal warehouse service and seamless logistics. Let's address some of the most pressing warehouse logistics challenges below.

1. Inventory Inaccuracies

One of the most pressing challenges faced by warehouses is inventory inaccuracies. Customers want their orders to be accurate and expect them on time, but it cannot happen when your inventory suffers from inaccuracies, leading to problems such as:

- Improper stock levels

- Obsolete inventory

- Order mistakes

- Returned or canceled orders

Manual methods of tracking inventory often lead to inaccuracies and time wastage. Automated software can make your life much easier by providing real-time statistics and enhanced visibility and efficiency.

2. Duplicate Processes

Duplication is also a major challenge for many warehouses. Eliminating it alongside unnecessary handling can save you a lot of time and money. When there are multiple workflows, paper-based sorting can lead to significant duplication.

Similarly, if the workflow isn't adequately communicated, numerous people might handle the same items at different times. It could easily result in shortages, lost items, overproduction, and whatnot.

The solution is quality warehouse management software that integrates easily with RFID and barcode technologies. It can automatically update inventories, invoices, payments, and other related information.

3. Poor Warehouse Layout

The warehouse layout is a critical component that can help reduce errors, enhance visibility, minimize accidents, and design the best route for order fulfillment. Doing it manually is error-prone and takes a lot of time. Warehouse management software can map the location in 3D after calculating accessible space vertically and horizontally and identify obsolete inventory, taking up space unnecessarily. The software has several ways to identify inventory, such as RFID, order numbers, types, batch numbers, expiry, and the like.

Manage Your Warehouse With Itefy

Warehouse management can be stressful if done manually, which is why automation is the answer. Itefy has an industry-leading Asset Management System that, with its incredible features, can make your life way easier. From preventing equipment loss to tracking condition to check out, it has everything that a diligent warehouse manager needs.

So, why wait when you can enjoy a free 14-day trial? Register with us today and pick a bundle when the trial is over.